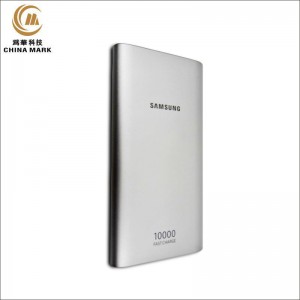

Aluminium extrusion suppliers, Radar fitting-base | WEIHUA

Custom Aluminum Extrusion Companies

As one of the China’s most professional custom Aluminum Extrusion suppliers, Weihua technology offers customers over 27 years of expertise in the industry and can give innovative and reasonale solutions that will meet your most complex design requirements.

Contact us, we are the supplier you always need to find and the most suitable supplier for you.

Process characteristics of aluminum extrusion

1. During the extrusion process, the extruded metal can obtain a more intense and uniform three-way compression stress state in the deformation zone than rolling forging, which can give full play to the plasticity of the processed metal itself;

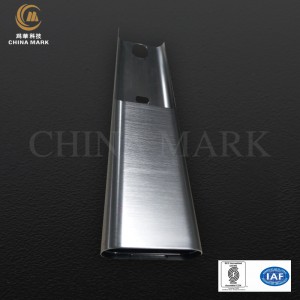

2. Extrusion molding can produce not only rods, tubes, shapes, and wire products with simple cross-sectional shapes, but also profiles and tubes with complex cross-sectional shapes;

3. Extrusion molding has great flexibility. It only needs to replace the extrusion tools such as molds to produce products with different shapes, specifications and varieties on one equipment. The operation of replacing extrusion molds is simple, fast, time-saving and efficient;

4. The precision of extruded products is high, the surface quality of the products is good, and the utilization rate and yield of metal materials are improved;

5. The extrusion process has a good effect on the mechanical properties of the metal;

6. The process flow is short and the production is convenient. One-time extrusion can obtain an overall structure with a larger area than hot die forging or forming rolling. The equipment investment is low, the mold cost is low, and the economic benefit is high;

7. Aluminum alloy has good extrusion characteristics, and is particularly suitable for extrusion processing. It can be processed by a variety of extrusion processes and a variety of mold structures.

Advantages of aluminum extrusion

Less machining:

As the aluminum alloy can be extruded into any complex section, as long as the design is reasonable, the extruded material can also be easily assembled, thereby reducing the need for machining. Some shapes can only be obtained by extrusion, which cannot be achieved by other processes.

Low mold cost:

Compared with other competitive materials such as rolling, casting, forging, etc., the mold cost of aluminum extrusion is lower.

High structural efficiency:

Aluminum extrusion materials can achieve maximum structural efficiency. You can use the profile where you need to increase the strength, and remove the profile where you don't need it.

Light weight:

The extruded aluminum profile is light in weight, high in strength, and durable. Due to the difference in performance between aluminum and other competing materials, the weight of aluminum structures that achieve the same effect is only about half that of other metal structures, and other metals are not easy to process.

Various surface treatment effects and strong corrosion resistance:

through powder or electrophoretic coating, designers can achieve any desired color. Of course, it also includes natural silver or color anodic oxide film.

Low maintenance:

Aluminum is a natural and durable metal, and the above-mentioned surface treatment enhances its durability.

The main process shows as below

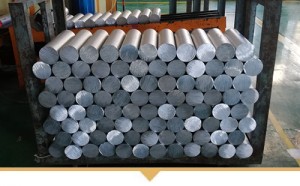

Step 1:6063 round bar ?100*350MM

Step 2:Natural gas environmental protection aluminum rod heating furnace

Step 3:Electromagnetic mold heating furnace

Step 4:1000 tons of high-precision profile extruder

Step 5:Natural gas environmental protection aluminum aging furnace