Aluminium name plate,High polished diamond cutting sound nameplate | WEIHUA

Aluminium Metal Signage

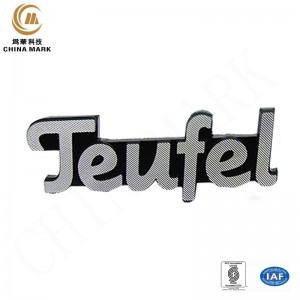

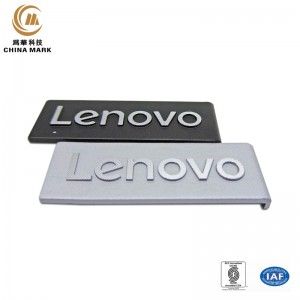

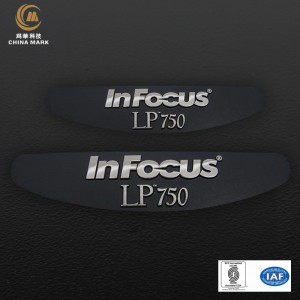

We are the front-runner status in the industry which deals in the offering of Aluminium Name Plate to the clients. Basically, these Aluminium Name Plates are used for a place the name of a person, company, etc. used widely in industrial machinery and equipment, office sign, outdoor, traffic signs, kitchen furniture, electrical appliances, air conditioners, televisions, navigators, auto parts, doors, sliding door, security doors, bathroom, audio, luggage, All kinds of wine boxes, tea packaging boxes, moon cake packaging, gift packaging boxes and other product LOGO signs.

We will introduces the processing methods of aluminum signs briefly :

(1) There are several ways to deal with font colors.

a. Silkscreen processing.

After the product font is highlighted, it is necessary to make different colors on the raised fonts, which can be achieved by silk-screening. The fonts on the same plane can be silk-screened in multiple colors. Each color must be screen-printed and dried in the oven. Screen printing in other colors (this kind of sign is called a metal silk screen sign).

b. Electroplating treatment.

After the sign font is highlighted, different colors can be electroplated according to customer requirements, the most common ones are gold and silver.

c. Paint.

The bottom painting method is the same as mentioned earlier

(2) Font highlight processing.

Carve off the paint on the surface of the sign with a diamond knife (also known as a diamond cutting, the normal gradient of the grain is 45 degrees, and different grains can be made according to customer requirements, usually including forward twill texture, reverse twill texture,arc texture, straight texture, and CD texture, Sun pattern texture, etc.).

People also ask

Do you need to order a custom nameplate in any shape? Please contact us as soon as possible, our goal is to always provide you with the highest quality nameplate.

Our high-power laser cutting machine can process any nameplate of standard shapes/materials for you.

The main process shows as below

Step 1:St.St. plate

Step 2:Laser cut according to the engineering dwg

Step 3:Film or coating in the dust-free shop, light exposure imaging

Step 4:Etching, ie, remove material by way of chemical reaction or physical corrosion

Step 7:Industry oven, hi-temp, low-temp & constant temp.

Step 5:Get deepened by etching once, and texture finish by twice etching, like snow grain.

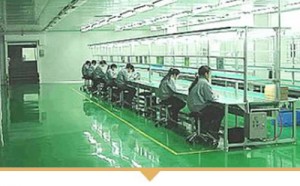

Step 8:Professional inspectors and packaging workers

Step 6:Done in the dust-free shop, by professional workers and advanced equipment

Step 9:Applied as precision etched parts for the electronic thin components for the aviation industry, machinery and chemical industry