Aluminium nameplates,Aluminum Diamond cutting with back pin metal engrave logo | WEIHUA

Compared with signs of other materials, aluminum signs have the following characteristics:

Aluminum is not only dirt-resistant but also corrosion-resistant;

If you need a metal nameplate, it can withstand harsh environments and keep it in good condition after direct contact, such as sunlight, rain, snow, dust, dirt and chemicals, then aluminum signage is your best choice; aluminum can survive when exposed to the ultraviolet rays of the sun and can even resist the corrosion properties of certain chemicals, so aluminum is also resistant to rust.

Aluminum is extremely lightweight;

If you need a lightweight metal, then aluminum is what you need. Aluminum nameplates are very light and can be easily installed on walls and doors using adhesives. Other metals may be quite heavy and require the use of mounting screws and rivets. If you don't want to make holes in the wall or mount your metal plate on the door, aluminum is definitely your choice, because it can be installed without these heavy hardware.

Aluminum is very cheap;

One of the most prominent advantages of aluminum is its low cost. You can use aluminum nameplates to save costs for other plates, and a small portion of them can use other types of metals or materials. In this way, you can not only get a high-quality metal nameplate to create demand, but also save costs.

Aluminum has strong plasticity;

Aluminum nameplates can be presented in many different ways. You can create your design in these plates. In many different places, you can also choose to use sandblasting, spraying, electroplating, wire drawing, engraving, etching, and silk screen printing, anodizing and other more processes to make aluminum signs.It’s very changeable.

The main process shows as below

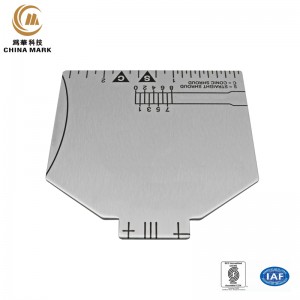

Step 1:St.St. plate

Step 2:Laser cut according to the engineering dwg

Step 3:Film or coating in the dust-free shop, light exposure imaging

Step 4:Etching, ie, remove material by way of chemical reaction or physical corrosion

Step 7:Industry oven, hi-temp, low-temp & constant temp.

Step 5:Get deepened by etching once, and texture finish by twice etching, like snow grain.

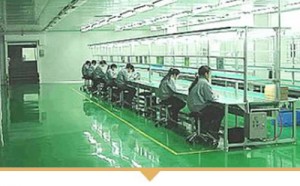

Step 8:Professional inspectors and packaging workers

Step 6:Done in the dust-free shop, by professional workers and advanced equipment

Step 9:Applied as precision etched parts for the electronic thin components for the aviation industry, machinery and chemical industry