Aluminum enclosures,Aluminum extrusion cases | CHINA MARK

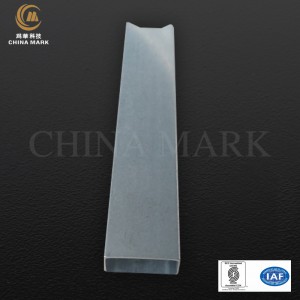

Aluminum Enclosures

| Description | We use high-precision aluminum extrusion extruder and high-purity 6063 aluminum rods, through customized processing of profile molds, producing various types of?aluminum extrusion box |

| Processing | Alum bar heating machine-Raw material extrusion-Aging-Precision cutting-Full inspection-Package-Delivery |

| Application | ? |

| NW | ?6g |

| Mold | ?Alum extrusion mold |

| LT | ?10 days |

| Type | ?OEM Parts |

| Mass production Lead time | 4weeks |

?

Hot: aluminum extrusion box;Advantages: rich experience/trustworthy;Weihua technology - can focus on: aluminum alloy extrusion, production and processing for more than 20 years, word of mouth manufacturers rich experience, meticulous workmanship, customized supply, welcome to consult!

?Advantages of extruded aluminum enclosure:

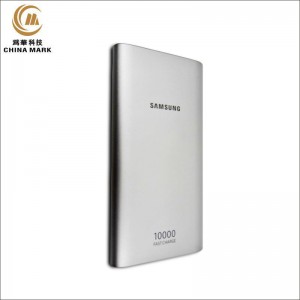

Aluminum shell is in aluminum stretching way get the shell on the aluminum processing, high flexibility, depth can be arbitrary cutting, general internal circuit board slot, as long as the circuit board can be inserted directly, without any fixed, convenience is unmatched by other types of shell, aluminum shell water proofing property is generally poor, however, is not suitable for use in field and harsh place.This kind of shell has a wide application prospect.

?

The main process shows as below

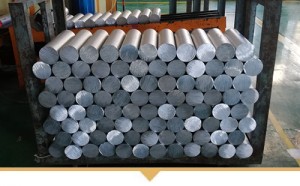

Step 1:6063 round bar ?100*350MM

Step 2:Natural gas environmental protection aluminum rod heating furnace

Step 3:Electromagnetic mold heating furnace

Step 4:1000 tons of high-precision profile extruder

Step 5:Natural gas environmental protection aluminum aging furnace

Step 6:Double-rail type automatic sawing machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA