Aluminum extruded enclosure | WEIHUA

Weihua technology is a professional production of?aluminum extrusion enclosure manufacturers, aluminum profile shell, mobile power supply aluminum shell, aluminum profile shell processing, and other products that sell well at home and abroad;

In recent years, due to the pursuit of miniaturization and lightweight, aluminum and aluminum profiles are widely used in construction, transportation, electronics, aerospace, and other industries.

Therefore, the proportion of?aluminium extrusion enclosure products also increased rapidly, according to the data show that extrusion processing products aluminum and aluminum products accounted for more than 70%.

Extruded aluminium enclosures, selected as China science and technology, professional manufacturing enterprises, cheap quality, good quality, reasonable price, perfect service, welcome online consultation ~

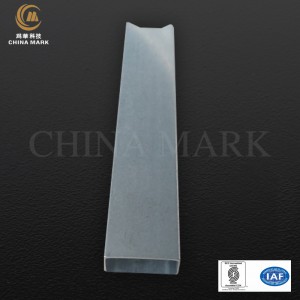

Process: The aluminum extruded shell is using aluminum rods through the aluminum extrusion process, with different shapes of molds, to extrude all kinds of aluminum housings of different shapes you want. Then it can be matched with powder coating process, anodizing process, CNC and other processes as secondary processing.

Production process: aluminum extrusion + stretching + aging + laminating + slitting + cleaning + full inspection + packaging

Size: 80mm*60mm*20mm (3.15*2.36*0.79 inch) or customized according to the drawing size.

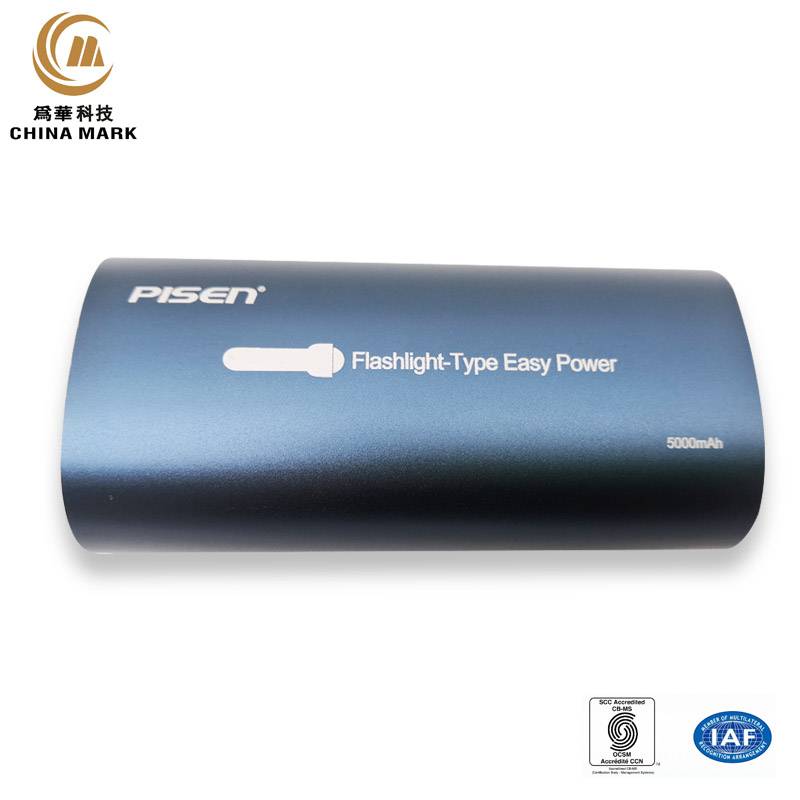

Function: The light purple sandblasted aluminum shell shown in the figure is the shell that used on the power bank. In addition, the aluminum shell can also be applied to various electronic cigarettes, battery tubes, and flashlights.

Aluminum Extrusion Box

| Description | We use high-precision aluminum extrusion extruder and high-purity 6063 aluminum rods, through customized processing of profile molds, producing various types of charging babies |

| Processing | Alum bar heating machine-Raw material extrusion-Aging-Precision cutting-Full inspection-Package-Delivery |

| Application | Xiaomi outer case |

| NW | ?85g |

| Mold | ?Alum extrusion mold |

| LT | ?10 days |

| Type | ?OEM Parts |

| Mass production Lead time | 4weeks |

?

Learn more about WEIHUA products

People also ask

The main process shows as below

Step 1:6063 round bar ?100*350MM

Step 2:Natural gas environmental protection aluminum rod heating furnace

Step 3:Electromagnetic mold heating furnace

Step 4:1000 tons of high-precision profile extruder

Step 5:Natural gas environmental protection aluminum aging furnace

Step 6:Double-rail type automatic sawing machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA

Q: What is the difference between aluminum and extruded aluminum?

A: Aluminum is a kind of material, and extruded aluminum refers to extruding the material through physical pressure, and then cutting, surface treatment and other methods to make aluminum profiles of various shapes and uses. This is called extruded aluminum.

Q:How much does an aluminum extrusion die cost?

A: According to different product structures, mold costs are different. The simple ones are generally around $390~$800 , and the complicated ones have a cost of $3XX to $1XXXX of molds.

Q:How do you make aluminum enclosures?

A: Production process: raw material (aluminum rod)-aluminum rod / mold preheating-extrusion-water.cooling-slitting-stretching-slitting-framing-aging-film-fine cutting-cleaning -Full inspection-packaging

Q:Is extruded aluminum stronger than steel?

A: Steel is stronger than extruded aluminum.