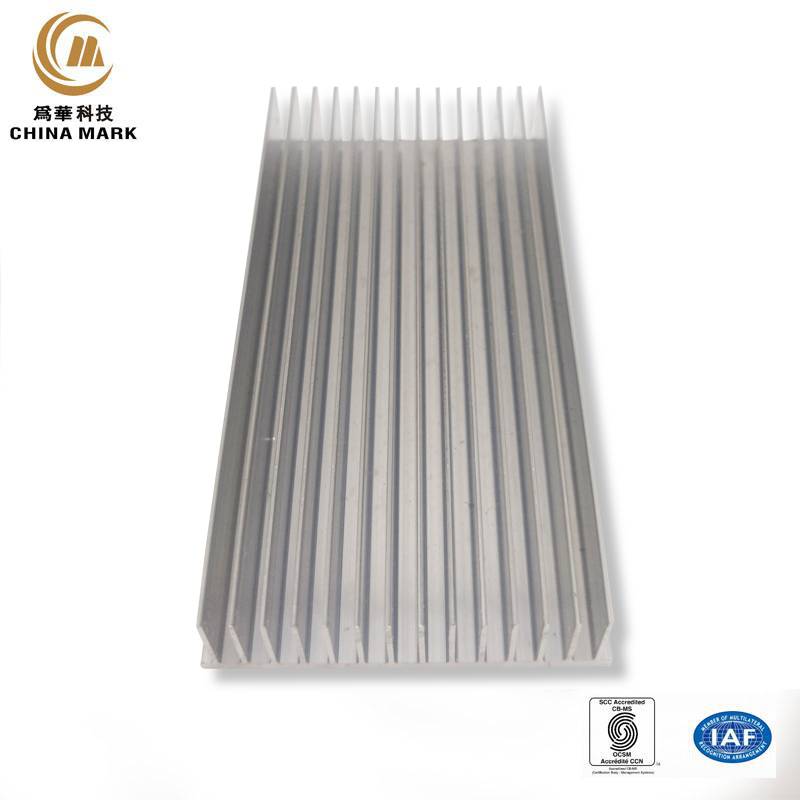

Aluminum Extrusion Heatsink for High-end Computer’s Heatsink | WEIHUA

Aluminum Heat Sink Extrusion

| Type | Aluminum extrusion |

| Processing | Aluminum extrusion+CNC+Sandblasting+Anodized? |

| Application | Suitable for high-end computer's heatsink |

| Process advantages | Precision aluminum extrusion,tooth height 10mm, tooth width 0.5mm, and will not deform |

| Meterial | ?AL6063 |

| Name | Heatsink |

?

Aluminium extruded heat sinks

This is widely used in modern heat dissipation of excellent heat dissipation materials, most of the industry use 6063 T5 quality aluminum, its purity can reach more than 98%, its heat conduction ability is strong, small density, cheap price, so it has been favored by the major manufacturers.

According to the thermal resistance of Intel and AMD Cpus and their heat output, aluminum extrusion manufacturers make the corresponding mold, heat the aluminum ingot to a certain temperature, so that its physical shape can be changed, and then out of the mold, we can get all kinds of raw heat sinks we want.It will be cut, groove, grinding, deburring, cleaning, surface treatment can be used.

Extruded heat sinks to pay attention to the "three temperatures" :

"Three temperature" refers to: mold temperature, aluminum bar temperature, extrusion cylinder temperature.

Mold temperature:

The mold is the key part of aluminum profile forming, the temperature must be kept at about 426℃, too high too low.

Aluminum bar temperature:

Aluminum rods need to be preheated before extruding to a temperature between 400 and 540 ° C. Alloys like 6063 need to be heated to 470 to 500 ° C.The aluminum bar will generate heat during extrusion, raising the temperature of the extrusion container, so its temperature should be strictly controlled.

Temperature of the extrusion container:

The temperature of the extrusion cylinder is between 500℃ and 570℃.

The main process shows as below

Step 1:6063 round bar ?100*350MM

Step 2:Natural gas environmental protection aluminum rod heating furnace

Step 3:Electromagnetic mold heating furnace

Step 4:1000 tons of high-precision profile extruder

Step 5:Natural gas environmental protection aluminum aging furnace

Step 6:Double-rail type automatic sawing machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA