Aluminum extrusions supplier,Suitable for heatsink | WEIHUA

Aluminum alloy is widely used to make heat sink materials because of its light weight, beautiful appearance, good thermal conductivity, and easy processing into complex shapes. There are three main types of aluminum alloy heatsink materials: flat and wide, comb-shaped or fishbone-shaped; round or elliptical radiating fins; tree-shaped.

Their common characteristics are: the distance between the radiating fins is short, a groove is formed between two adjacent radiating fins, and the aspect ratio is large; the wall thickness difference is large, the general radiating fin is thin, and the bottom plate thickness at the root is large. Therefore, it brings great difficulty to the mold design, manufacture and production of heat dissipation profiles.

At present, the heatsinks used in foreign countries are generally made of aluminum extruded profiles, but the traditional cast aluminum heatsinks are still used in China and above. The process performance and efficiency of the cast aluminum heatsinks are low. Aluminum heatsinks are used instead of cast aluminum heatsinks. It is imperative. Weihua Technology has been professionally producing aluminum extruded heatsinks for many years, and can provide you with high-efficiency and high-performance heatsinks.

Whether you are designing a computer, LED lighting or other electronic equipment, you need a heat sink. The heatsink absorbs and dissipates the heat of these devices to cool them.

Today, we will discuss some different types of heatsinks, their manufacturing methods and their applications.

When discussing different types of heatsinks, we usually classify them according to their manufacturing process.

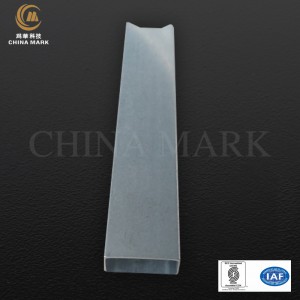

1-Extruded heatsink

Most heatsinks are made of extruded aluminum. Extruded heatsinks are inexpensive and can be easily manufactured to custom specifications. The performance of the extruded heatsink ranges from low to high.

2-Heat sink

The heat sink produced by this method is usually made of copper. They are made of solid metal blocks. These heat sinks have high design flexibility, and you can achieve high fin density. This creates greater surface area and opportunities for heat dissipation.

3-Stamping heatsink

These are usually used for low power applications. The advantage of stamping heatsink is that because it is easy to realize production automation, its cost is very low.

4-Forged heatsink

Forged heatsinks are made by compressing aluminum or copper and have many applications. The heatsink can be cold forged or hot forged. These products have medium performance and can be produced in large quantities at low cost.

The main process shows as below

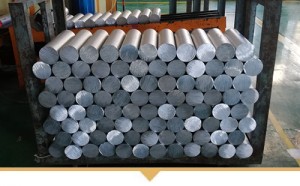

Step 1:6063 round bar ?100*350MM

Step 2:Natural gas environmental protection aluminum rod heating furnace

Step 3:Electromagnetic mold heating furnace

Step 4:1000 tons of high-precision profile extruder

Step 5:Natural gas environmental protection aluminum aging furnace

Step 6:Double-rail type automatic sawing machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA