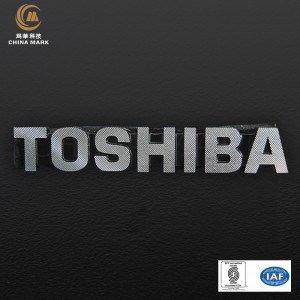

Metal nickel nameplates,Nameplate for printer | CHINA MARK

Metal Nameplate

| Material | usually use the annealed alum |

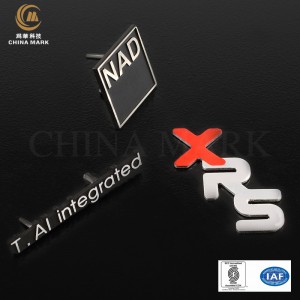

| Process | -Alum cut+forge+stamp+paiting+brush-to get every kind of LOGO-by cold forging process,

-further combined with painting or anodizing, -and using diamond tools to get the carving finish or CD grain. , |

| Application | Nameplate for printer |

| NW | ?18g |

| Mold | ?Tool opening |

| LT | ?15 days |

| Type | ?OEM Parts |

| Mass production Lead time | 4weeks |

?

Anodized aluminum nameplate

As is known to all, aluminum oxide film has valuable corrosion resistance, stability and color absorption and a series of advantages in the nameplate protection decoration has been widely used.Therefore, it is unnecessary to repeat its mechanism, equipment and general operation method.

Aluminum oxide electrolyte, although there are oxalic acid, chromic acid and sulfuric acid types, from the nameplate process practicality and decorative considerations, only the application of the most popular sulfuric acid electrolyte process specifications are introduced here;At the same time, it also introduces some new technological methods for the practical application of nameplate production.

Sulfuric acid solution oxidation is the most typical method in nameplate industry, which has the following characteristics.

(1)?The film layer is thicker, the surface color is transparent colorless, strong adsorption, is conducive to a variety of bright colors.

(2) simple process, short oxidation time, high production efficiency;

(3) the tank is cheap, stable solution, easy to grasp;

Etching nameplate, metal etching, engraved brass luggage tag, weihua technology (nameplate manufacturer) professional manufacturers, environmental protection etching equipment, stainless steel copper and aluminum etching, spot wholesale, non-standard products, good finish, beautiful appearance, precision processing, manufacturers direct, industry leader, welcome to customize ~

You may also like:nameplate for speaker;Please click to view ~

The main process shows as below

Step 1:Alum plate

Step 2:Laser cut according to engineering dwg

Step 3:Air-driven punching machine

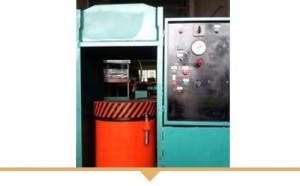

Step 4:Forging device

Step 7:Exquisite nameplate

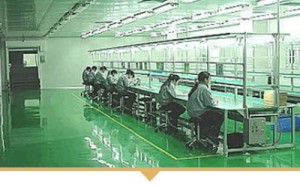

Step 5:Auto line of anodic oxide processing

Step 8:Professional inspectors and packaging workers

Step 6:Auto oil-dripping machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA