Anodized aluminum nameplates,OEM blue anodized sign white CD texture badge custom logo tag | WEIHUA

?Although the materials used to make metal signs are stainless steel, aluminum, or nickel, most of the materials used to make anodized metal nameplates are aluminum.

We not only can make aluminum diamond engraved anodized signs, aluminum extrusion anodized shells, aluminum screen printing and brushing machine signs, but also various other customized metal tags with different colors.

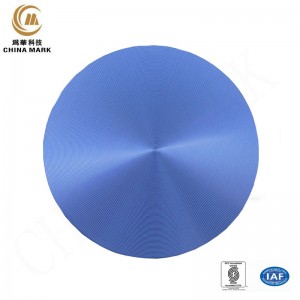

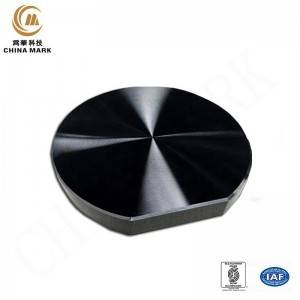

Among them, the most common are OEM white anodized aluminum signs, black anodized signs, blue anodized signs, red anodized signs, orange anodized signs, green anodized signs, etc. These kind of nameplate are with rich color to choose.

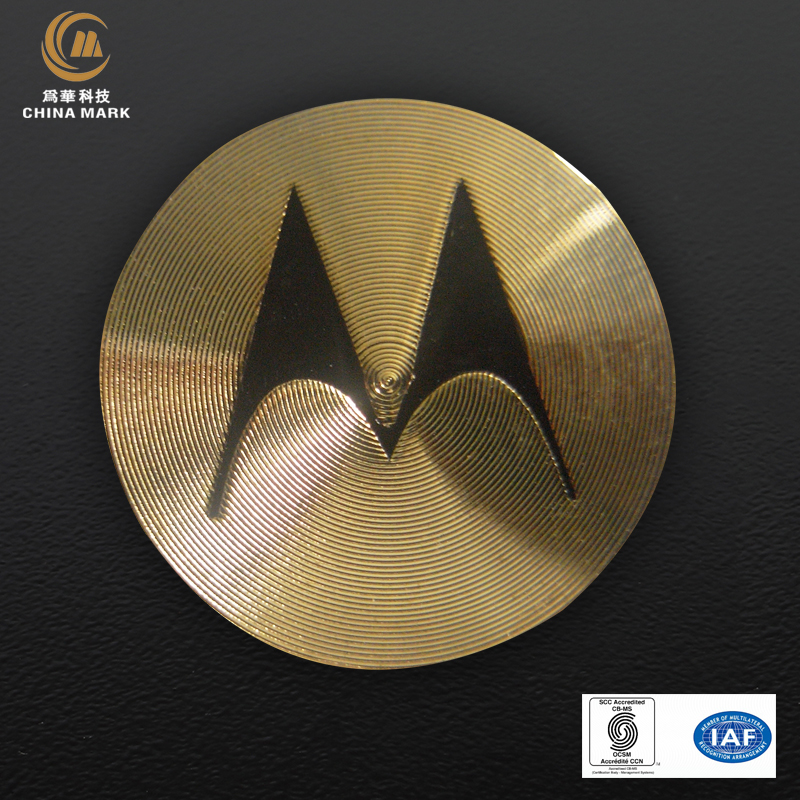

This also urges many audio manufacturers, earphone manufacturers, TV manufacturers, microwave oven manufacturers, refrigerator manufacturers, etc. to choose custom anodized signs, because this type of sign has a lot of color choices, and can do different surface techniques (such as CD pattern , Laser carving, diamond engraving, etc.), which can make their products look more fashionable, beautiful and light luxury.

MANUFACTURING OF CUSTOM METAL NAMEPLATES

Our high-tech laser marking and engraving machine can create a high-end and delicate & durable logo and fonts on the custom engraved signages.

All signs are unique, each has its own pattern, logo, font and meaning, just like a person's name, it has a special meaning. Our design and R&D department for Hua Technology can customize their unique signs for customers, such as company promotional signs, office staff position signs and so on.

?

Our signs mainly include the following processes, processing and installation methods, which can be used for customers' reference

(1) Common process:

a. Embossed and Recessed (stamping), forging, high-gloss diamond cutting, chemical etching, anodizing, wire drawing, laser engraving, electroplating, spraying, screen printing and other production processes.

(2) Font processing method:

a. Highlight processing. That is, use a diamond knife to carve off the paint on the surface of the sign (also known as diamond cutting, the normal gradient of the grain is 45 degrees, and different grains can be made according to customer requirements, usually including forward twill grain, reverse twill grain, arc grain, straight grain, CD pattern, sun pattern, etc.).

b. Brushing treatment. Use a brushing machine to pull off the paint on the surface of the sign. The texture can be selected according to customer requirements.

c. Sandblasting. The sandblasting process is more complicated than the above two types. After sandblasting the entire sign, it must be oxidized after sandblasting.

(3) Installation method of aluminum signs:

a. Aluminum signs with pins. The mold can be made according to the foot length, foot diameter, and center distance required by the customer. After the sign is die-cast, the sign itself will have its own spikes. There are many ways to install such signs with feet, such as bending the feet and fixing them behind the panel.

b. Adhesive aluminum signs. Different adhesives for aluminum signs can be applied according to customer requirements, such as ordinary glue, 3M glue, Desa glue, sponge glue, etc. Most customers commonly use 3M glue. This kind of installation is simple, just remove the layer of paper on the surface and paste it directly.

c. The bottom of the aluminum sign is punched. This type is mainly used to fix the sign on the product by nails. This type of furniture industry is more commonly used, and it is rarely used in other industries.

Generally speaking, aluminum signs are one of the most cost-effective signs. When you order aluminum signs, you can first learn more about the process of aluminum signs, so that you can make signs that best suit your needs.

Learn more about WEIHUA products

The main process shows as below

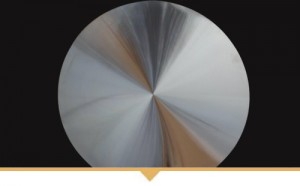

Step 1:All series of alum plate

Step 2:Auto cut, by adjusting the parameters per the engineering dwg

Step 3:Neat & clean stamping workshop

Step 4:Machine the CD grain

Step 7:Professional inspectors and packaging workers

Step 5:Excellent visual effect to show the high-end level

Step 6:Auto line of anodic oxide process

Q1: Can you stamp anodized aluminum?

A: Yes, we can stamp anodized aluminum texture nameplate and anodized aluminum extrusion housing case.

Q2: Does anodized aluminum wear off?

A: Not, it won’t be fade off because with solid color. It can be used in indoor and outdoor. Like speaker nameplate,earphone logo and outdoor audio signage.

Q3:What is the disadvantage of anodized aluminum?

A: The cost will be higher than other metal nameplates.

The process will be a little more complex than other badges.

Q4: Is anodized aluminum good for outdoors?

A: Yes, anodized aluminum nameplate with good solid color and anti-scratch,anti-rust advantages. Thus, it’s suitable for outdoor use.