Brushed nameplate,Socks custom logo | WEIHUA

Wire brushing signs are mainly divided into wire brushed aluminum metal plate, stainless steel wire brushed signage, brushed brass nameplate and other materials. It is mainly used in 3C electronics industries such as mobile phones (such as mobile phone cases, computer cases, etc.), household appliances industries (such as cabinets, microwave ovens, desks, etc.) and other industries.

The following mainly introduces the main brushed textures applied to metal signs:

(1) Straight wire brushing

Straight wire brushing refers to processing straight lines on the metal surface by mechanical friction. It has the dual function of removing scratches on the metal surface and decorating the metal surface. There are two types of straight wire brushing: continuous wire and intermittent wire. The continuous thread pattern can be obtained by using a scouring pad or a stainless steel brush through continuous horizontal linear friction on the metal surface. By changing the wire diameter of the stainless steel brush, textures of different thicknesses can be obtained. Intermittent silk patterns are generally processed on brushing machines or rubbing machines.

(2) Random pattern brushing

Chaotic wire brushing refers to the movement of metal back and forth and left and right under the high-speed rotating copper wire brush, so as to obtain a kind of irregular and non-obvious matte silk pattern. This processing technology has high requirements on the surface of the metal.

(3) Swirl wire brushing

Swirl is also called optical rotation. It is a kind of silk pattern obtained by using cylindrical felt or grindstone nylon wheel on a drilling machine, blending polishing oil with kerosene, and rotating and polishing the metal surface. Swirl brushing is mostly used for decorative processing of round signs and small decorative dials.

(4) Corrugated wire brushing

Generally, it is made on a brushing machine or a rubbing machine. Use the axial movement of the upper group of grinding rollers to brush on the surface of the aluminum or aluminum alloy plate to obtain a wave pattern

Do you need to order a custom nameplate in any shape? Please contact us as soon as possible, our goal is to always provide you with the highest quality nameplate.

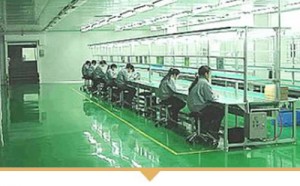

The main process shows as below

Step 1:St.St. plate

Step 2:Laser cut according to the engineering dwg

Step 3:Film or coating in the dust-free shop, light exposure imaging

Step 4:Etching, ie, remove material by way of chemical reaction or physical corrosion

Step 7:Industry oven, hi-temp, low-temp & constant temp.

Step 5:Get deepened by etching once, and texture finish by twice etching, like snow grain.

Step 8:Professional inspectors and packaging workers

Step 6:Done in the dust-free shop, by professional workers and advanced equipment