Copper name plate,Alum cut,Forge,Nameplate of earphone | CHINA MARK

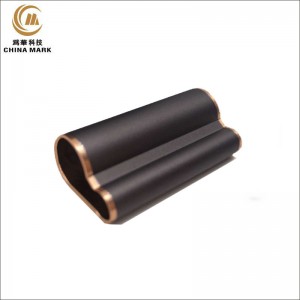

Copper name plate

| Material | Usually use the Alum plate or copper under 1mm THK |

| Process | - Alum cut+forge+stamping+CD brush+anodize+oil-dripping- by stamping or cold pressing technique,

- To get each kind of concentric grain effect by the hi-precision full auto CD grain machine, - To achieve each colorful part by further combining with the anodizing or galvanizing process; |

| Application | Nameplate of earphone |

| NW | ?10g |

| Mold | ?Tool opening |

| LT | ?15 days |

| Type | ?OEM Parts |

| Mass production Lead time | 4weeks |

?

Below, we will introduce copper briefly:

(1) What are the main types of copper?

H96 copper, H90 copper, H85 copper, H70 copper, H68 copper, H65 copper, H63 copper, H62 copper, H59 copper, of which H85 and H70 are mainly used for metal signs.

(2)What are the characteristics and application scope of H85 and H70 copper?

H85 copper is composed of 85% copper and 15% zinc alloy. H85 copper has good mechanical properties and corrosion resistance, excellent cold working performance, and good hot formability; H85 copper is used in earphone signs, door signs, It is widely used in industries such as indoor clothes cabinets and other hardware micro-chapters, cooling equipment parts, etc.

H70 copper is composed of 70% copper and 30% zinc. H70 copper has higher plasticity and higher strength, good cold formability, easy welding, and good corrosion resistance. H70 copper is widely used in furniture , retro audio metal logo, perfume metal bottles and other signs and labels, office desk embossed products, etc.

(3) What are the advantages of copper?

1. Ordinary copper not only has excellent mechanical properties, but also has strong corrosion resistance and processing properties

2. copper has good ductility, is easy to process, and is very stable in a dry environment, so most of the time it is used for indoor signage.

3. copper has a strong sense of texture, luster, heat conductivity and etching processability, and can be made into retro, elegant and luxurious tags

4. Low price,low cost,simple process, so copper is the first choice for electroforming nameplates

5. There are many classical colorings of copper and copper alloys, such as bronze, antique black, bronze rust, red, green, blue, brown and black, antique green, chocolate, etc.

6. copper can be made into etched copper signs, brushed copper signs, laser cut engraved signs and electroforming gold-plated signs, especially electroforming signs, which are generally only 0.1~0.2mm in thickness and can be made into special shapes , Arc surface, three-dimensional three-dimensional and other complex shapes

Learn more about WEIHUA products

The main process shows as below

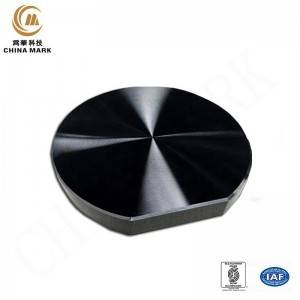

Step 1:All series of alum plate

Step 2:Auto cut, by adjusting the parameters per the engineering dwg

Step 3:Neat & clean stamping workshop

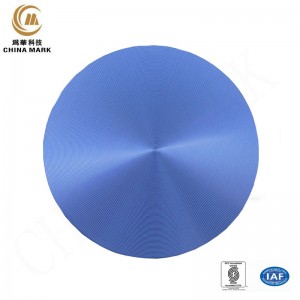

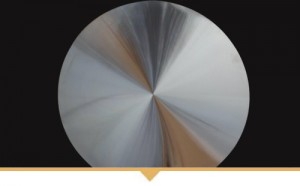

Step 4:Machine the CD grain

Step 7:Professional inspectors and packaging workers

Step 5:Excellent visual effect to show the high-end level

Step 6:Auto line of anodic oxide process

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA

We were completely satisfied – it was beautiful!?

![]() ?By Renata from Malaysia – 2020.04.19 13:51

?By Renata from Malaysia – 2020.04.19 13:51

The carving is well done and the price is good

![]() ?By Lulu from Washington – 2020.03.27 12:26

?By Lulu from Washington – 2020.03.27 12:26

We were able to find what we wanted on line, service excellent, and delivery arrived much quicker than originally scheduled.?All in all a very satisfactory purchase.

![]() ?By Kathy from Washington – 2019.12.17 10:20

?By Kathy from Washington – 2019.12.17 10:20