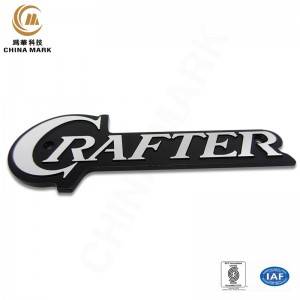

Custom aluminum nameplates,High polished diamond cutting nameplate | WEIHUA

Custom metal nameplates

Our Weihua technology custom metal aluminum nameplates have been enduring for a long time and have been sold in large quantities at home and abroad for a long time. The main reason is that aluminum plates are the most decorative parts. Many surface decoration techniques can be applied and exerted on aluminum. , It is convenient to obtain colorful and various combinations of high-level decorative layers.

At the same time, it is widely used in various industries (such as: electronics, electrical appliances, industrial machinery and equipment, air conditioners, televisions, automobiles, automobile and motorcycle accessories, furniture, kitchenware, office supplies , Bathroom, audio, accessories, various wine boxes, tea packaging boxes, gift packaging boxes and other product LOGO signs.

| Name | High polished diamond cutting nameplate |

| Type | Stamping nameplate |

| Process | Cutting+Stamping+Oil press+Blanking+Painting+Baking+Diamond cutting+Apply adhesive+Full inspection+Package |

| Application | High-end Crafter Electric Guitar |

?

Why our signs have been loved by customers and repurchased many times?

1. The high processing efficiency, good quality, and there is a very professional high-speed stamping equipment, which can meet the needs of the special process of the sign.

2. Good corrosion resistance. Using high-quality materials, the surface of the aluminum and its alloy signs produced can form a hard and dense oxide film, and it will have excellent durability when used in the harsh environment of industrial areas and coastal areas.

3. No magnetism. Aluminum signs will not cause external interference to the equipment.

4. Low cost, good quality, large capacity, which greatly meets the requirements of customers

5. An engineering and R&D technical team with more than 6 years of experience, the recommended solutions can greatly meet the special customization requirements of customers.

| Material: | Diamond cutting aluminum .020" standard (optional thicknesses .03", .06", .08",0.098”, .012", .032", .063", .090", .125" and other’s you want). |

| Process: | Material cutting+Stamping+Blanking+Silkscreen+Baking+Diamond cutting+Apply adhesive+Full inspection+Delivery |

| Surface Finishes: | Anodized, Reoxidation, Brushed,Sandblasting, Painting(Silkscreen),High gloss and requested surface finishing. |

| Attachment: | Permanent pressure-sensitive adhesive and/or holes for mechanical attachment. |

| Graphics: | All kinds of patterns & fonts & contact information are available, as well as your company logo or job title. |

| Adhesive: | 3M series tapes: 3M 9495LE,3M 9472LE,3M 5925,3M 468, 3M 467,3M 9448A,3M 200MP and other requested tape. |

| Sample time: | 1 weeks |

| Mass production time: | 2-3 weeks |

| Shipment: | Via Ocean / Sea or UPS / Fedex / DHL express or others you want |

People also ask

1.The surface treatment process of metal nameplate is introduced

2.How to make a metal nameplate

3.Metal Nameplate Properties And Scope Of Application

4.What Are The Defects That Are Easy To Produce When The Custom Metal Nameplate Is Rolled

5.?where can i get a metal nameplate made

The main process shows as below

Step 1:St.St. plate

Step 2:Laser cut according to the engineering dwg

Step 3:Film or coating in the dust-free shop, light exposure imaging

Step 4:Etching, ie, remove material by way of chemical reaction or physical corrosion

Step 7:Industry oven, hi-temp, low-temp & constant temp.

Step 5:Get deepened by etching once, and texture finish by twice etching, like snow grain.

Step 8:Professional inspectors and packaging workers

Step 6:Done in the dust-free shop, by professional workers and advanced equipment

Step 9:Applied as precision etched parts for the electronic thin components for the aviation industry, machinery and chemical industry

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA