Custom aluminum nameplates,Suitable for electronic cigarette sliding cover | WEIHUA

Since its establishment 27 years ago, Weihua Technology has focused on the production of each?metal nameplate?to inject vitality into each nameplate.

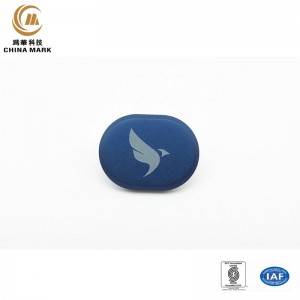

Custom aluminum nameplates

| Name: | Round laser craving nameplate |

| Type: | custom metal name plate |

| Overall Size: | 14.3*10.8*5.25mm( 0.56”x0.42x0.2”) or at your requested size |

| Material: | Aluminum, stainless steel, brass, nickel and others |

| Process: | CNC+Tapping+Grinding+Anodizing+Laser craving+Full inspection+Package?? |

| Customized Area: | Varies |

| Thickness: | 0.2” thickness or at your requested thickness |

| Shape: | ?Included -Square,Rectangle, Oval other shapes |

| Mounting: | Included - adhesive. Upgrades - holes with screws |

| Artwork File Types: | AI, STP, DWG, JPG, PDF, PNG or other file |

| Usage: | For electronic cigarette sliding cover |

| Indoor / Outdoor: | Indoor and outdoor use are ok. |

| Production Time: | 3-5 days for sample fnished after order placed. 3-7 days for mass production after sample approved. |

We accept orders for metal signs from large and small customers at home and abroad, and devote ourselves to providing customers with preferential, high-quality, design-like signs. There are mainly the following types of signs:

Anodized aluminum sign

Anodized aluminum signs are much stronger than ordinary aluminum plates. Both smoothness and flatness are better than ordinary aluminum plates. The colors of anodized aluminum plates are rich and colorful, and they have excellent rust resistance, wear resistance and good processing performance. It is easy to bend. We mainly make anodized aluminum logo. For example, audio signs such as JBL, HARMAN KARDOM and TEUFUL basically use this kind of anodizing process. This is why we are familiar with so many people in China.

Diamond carved signs

Diamond carving, commonly known as custom engraved signs. The most exquisite, beautiful and high-end sign. This is also our flagship sign. For example, JAMO, PHILIPS, AONI, COUGAR, etc. are all approved signs with the highest repurchase rate.

Customized laser engraving sign/e-cigarette LOGO

Laser engraving technology is a surface treatment process that uses laser high temperature to "burn out" part of the surface material of rubber and plastics to form characters and patterns. Among them, our main focus is the laser-engraved LOGO of e-cigarettes and e-cigarette sliders, such as the electroic cigarette logo and slidering cover such as Vita, Hengxin, RELX, Zhuoeryue, etc.

Printed aluminum sign

The screen printing range is very wide, and it can print all kinds of logo roots, panels, signs and metal moldings. However, metal products are durable goods and require higher surface decoration and durability. Therefore, surface treatments such as surface coating, electroplating, anodizing or wire drawing are often used before printing.

Stainless steel sign

Stainless steel signs are advertising signs made from stainless steel plates through corrosion, die-casting or other methods. Most of the stainless steel signs used at this stage are made by corrosion technology. Such signs have beautiful patterns and clear lines. Appropriate depth, smooth floor, full color, uniform drawing, consistent surface color and so on.

The surface effects of stainless steel signs can generally be made into: mirror polished, matte, sand, brushig, net, twill, CD, three-dimensional concave-convex and other surface style effects;

Do you need to order a custom nameplate in any shape? Please contact us as soon as possible, our goal is to always provide you with the highest quality nameplate.

Our high-power laser cutting machine can process any nameplate of standard shapes/materials for you.

People also ask:

The main process shows as below

Step 1:St.St. plate

Step 2:Laser cut according to the engineering dwg

Step 3:Film or coating in the dust-free shop, light exposure imaging

Step 4:Etching, ie, remove material by way of chemical reaction or physical corrosion

Step 7:Industry oven, hi-temp, low-temp & constant temp.

Step 5:Get deepened by etching once, and texture finish by twice etching, like snow grain.

Step 8:Professional inspectors and packaging workers

Step 6:Done in the dust-free shop, by professional workers and advanced equipment

Step 9:Applied as precision etched parts for the electronic thin components for the aviation industry, machinery and chemical industry