Custom extruded aluminum enclosures,Aluminum extrusion housing | WEIHUA

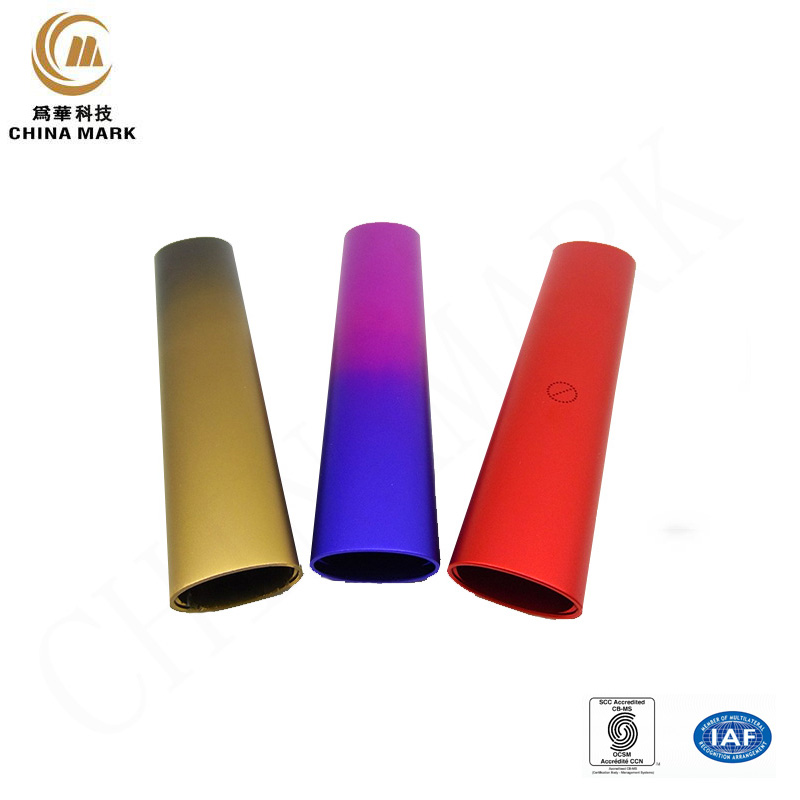

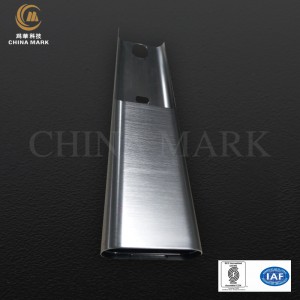

Custom aluminum extrusion housing

| Name | Aluminum Extrusion Box |

| Size: | customized size according to customer |

| Meterial | AL6061/ AL 6063 |

| Processing | Aluminum extrued+CNC machining+Polishing+Cleaning+Full inspection+Sandblasting/Anodizing+Laser craving+Full inspection+Delivery?? |

| Application | ? |

| Type | Aluminum extrusion |

?

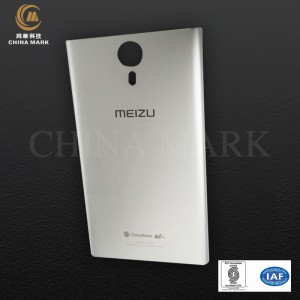

The above can be sprayed, CNC, sandblasted, anodized, brushed, CD pattern, laser engraved, etc. Aluminum housing is widely used in electronic instruments, meters, electronic communications, automation, smart cards, industrial control, precision machinery and other industries. It is an ideal housing for high-end instruments.

What’s the advantages of aluminum enclosures ?

1-, Aluminum shell is an alloy material with strong plasticity, has advantages in hardness, is not easy to deform, and the heat dissipation performance of aluminum shell is better, so the use of aluminum alloy to make the shell can not only achieve the heat dissipation effect, but also Ensure that it will not be deformed due to high temperature.It can also reduce the probability of accidents.

2- Aluminum housing also has good conductivity, not only inherits the conductivity of aluminum, but also has the ductility of aluminum. The aluminum shell is lighter in weight and beautiful in appearance, and is used in the production and processing of most products.

3- The corrosion resistance of the aluminum alloy shell makes it relatively low in the working environment when it is used. For example, the aluminum alloy charging pile shell can be used in areas with harsh weather. On the one hand, it can protect the inside of the power supply.

4-Aluminum alloy shell is not easy to get dirty, easy to clean and maintain, has stable chemical properties, and is non-magnetic, so it can be recycled and reused, which has a good protective effect on the environment.

Learn more about WEIHUA products

The main process shows as below

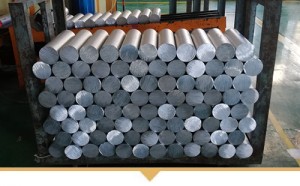

Step 1:6063 round bar ?100*350MM

Step 2:Natural gas environmental protection aluminum rod heating furnace

Step 3:Electromagnetic mold heating furnace

Step 4:1000 tons of high-precision profile extruder

Step 5:Natural gas environmental protection aluminum aging furnace

Step 6:Double-rail type automatic sawing machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA

1.What is an aluminum extrusion?

Answer: Aluminum rods are hot-melted and extruded to obtain aluminum materials with different cross-sectional shapes

2. Why aluminium is used for extrusion?

Answer: Aluminum has low hardness, good toughness, ductility and plasticity?advantage.?

3.How strong is 2020 aluminum extrusion?

Answer: Determine the size of the aluminum extrusion die according to the shape and size of the truncated surface, and then decide whether to use a face die or a split die.

4.Are extrusions made using aluminum?

Answer: Yes,Aluminum extrusion Raw material: aluminum rod