Custom extrusions aluminum,Aluminum extrusion housing | WEIHUA

Custom extruded aluminum

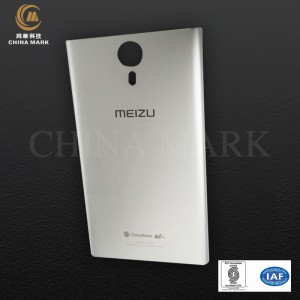

| Name: | aluminum extrusion box |

| Type: | Miniature aluminum extrusions |

| Size: | At your requested size |

| Material: | AL6061/ AL 6063 |

| Process: | Aluminum extrued+CNC machining+Polishing+Cleaning+Full inspection+Sandblasting/Anodizing+Laser craving+Full inspection+Delivery |

| Application: | ? |

?

The following briefly introduces the custom aluminum extrusion:

1. The principle of aluminum extrusion

Aluminum profile extrusion is a plastic processing method that applies external force to the metal blank placed in the container (extrusion cylinder) to make it flow out of a specific die hole to obtain the desired cross-sectional shape and size.

2, the classification of aluminum extrusion methods

Weihua Technology can be based on the type of metal in the aluminum profile extrusion cylinder, the extrusion direction of the aluminum profile, the lubrication state, the extrusion temperature, the extrusion speed, the type or structure of the mold, the shape or number of the blank, and the shape of the product. Or the number of different, complete the forward extrusion method, reverse extrusion method, side extrusion method and continuous extrusion method and so on.

3, the benefits of aluminum extrusion profiles:

Less machining:

As aluminum alloy can be kneaded into any messy cross-section, only reasonable planning is needed, and the kneading aluminum alloy profile can be easily assembled, and then the need for machining is reduced.

Low cost of aluminum kneading die:

Compared with other competing materials such as rolling, forging, and forging, the cost of aluminum kneading die is lower.

Light weight:

The kneaded aluminum alloy profile is light in weight, high in strength, and durable. Due to the difference in functions between aluminum and other materials, the weight of aluminum structures that perform the same function is only about half that of other metal structures, and other metals are not easy to process.

Versatile appearance treatment and strong corrosion resistance: After powder or electrophoretic coating, it can complete any desired color. Of course, it also contains natural silver or color anodic oxide film. Aluminum is a naturally used metal, and the above-mentioned exterior treatment enhances its durability.

4. Aluminum surface treatment method:

Weihua can realize integrated sandblasting, anodizing, laser carving, spraying, PVD (physical vapor deposition), polishing, metal brushing and other surface treatment processes, eliminating many intermediate links and completing a complete aluminum extrusion process.

5. Uses of aluminum profiles:

5052 this alloy has good forming and processing properties, corrosion resistance, weldability, fatigue strength and medium static strength. It is used to manufacture aircraft fuel tanks, oil pipes, large petrochemical equipment, and sheet metal parts, instruments, and transportation vehicles and ships. Street lamp bracket, etc.

6061 requires various industrial structural parts with certain strength, weldability, and high corrosion resistance, such as plates, tubes, rods, and profiles for semiconductor templates, transportation, and ships.

6063 Extrusion materials used in construction profiles, transportation, electronic furniture and other industries.

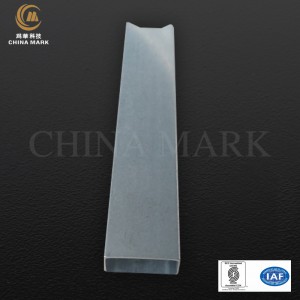

The main process shows as below

Step 1:6063 round bar ?100*350MM

Step 2:Natural gas environmental protection aluminum rod heating furnace

Step 3:Electromagnetic mold heating furnace

Step 4:1000 tons of high-precision profile extruder

Step 5:Natural gas environmental protection aluminum aging furnace

Step 6:Double-rail type automatic sawing machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA

How much does custom extruded aluminum cost?

Answer: About 300 USD-3500USD.Mainly,it depends on the difficulty of product processing and production management cost

Can you extrude aluminum?

Answer: Our company can make extruded profiles. According to the product precision requirements, different wall thicknesses have different tolerance standards, refer to GB/T national standards, such as:

How do you make aluminum extrusions?

Answer: Our company has aluminum extrusion machine,

Process flow: pre-production preparation (mold and aluminum rod heating) – extrusion – air cooling – sawing – aging (enhancing product hardness)

What type of aluminum is used on architectural extrusions?

Answer: According to different uses and requirements, the material of aluminum extrusion is also different. Commonly used aluminum extrusion materials are: 1000 series, 2000 series, 3000 series, 5000 series, 6000 series, 7000 series, etc.