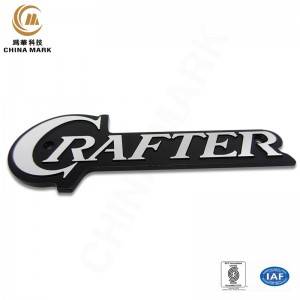

Custom logo plates,stamped anodized diamond cutting sign | WEIHUA

Custom logo plates, Laser engraving, etching, embossed, screen printing electroforming, logo & data name plates, aluminum, Anodized Aluminum, Brass......?

The?custom logo plates of other details of this sign:

1.The minimum order quantity is 1K

2.Unlimited number of first prototype

3.The mold opening time is 1-2 weeks, and the sample completion time is 3-5 days. For the first mold opening and proofing, 10-20 free samples can be provided

4.Quotation conditions are acceptable EXW Huizhou, FOB Shenzhen, CIF, etc.

5.Can receive express, sea, air and other transportation methods

The manufacturer of?custom metal logo tags?

If you are looking for a sign that can improve the recognition of your products and play a role in promoting your brand, we will be the right?custom metal logo tags supplier for you. As a product, signage can express the information you want to show to the public in a simple, straightforward, and well-written manner. You can add your company’s unique logo pattern or letter to the sign, or add your company’s website, email address, contact number, or add some machine information, etc.

Quick Q&A:

A1: We can produce many different types of hardware signs here, including aluminum stamping and printing signs, aluminum silk-screen printing signs, aluminum oil pressure signs, aluminum anodized signs, aluminum brushing signs, aluminum CD pattern signs, stainless steel etching signs, stainless steel stamping Signs, electroformed nickel signs, etc.

A2: Yes, as long as you are willing to bear the sample freight, we can provide 10-20 similar free samples for your reference.

A3: Yes. We can make signs with feet, the kind of signs that can play a fixed role.

For more details, please contact our sales staff directly. Email: wh@chinamark.com.cn, telephone contact: 0086+19926691505

Video:

The main process shows as below

Step 1:St.St. plate

Step 2:Laser cut according to the engineering dwg

Step 3:Film or coating in the dust-free shop, light exposure imaging

Step 4:Etching, ie, remove material by way of chemical reaction or physical corrosion

Step 7:Industry oven, hi-temp, low-temp & constant temp.

Step 5:Get deepened by etching once, and texture finish by twice etching, like snow grain.

Step 8:Professional inspectors and packaging workers

Step 6:Done in the dust-free shop, by professional workers and advanced equipment

Step 9:Applied as precision etched parts for the electronic thin components for the aviation industry, machinery and chemical industry