Custom metal labels,hardware sign manufacturer | WEIHUA

Custom metal labels of?manufacturer

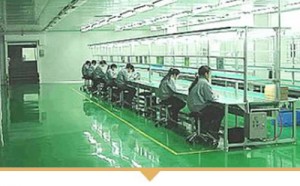

We have over 27 years of sign-making experience in the hardware sign industry, and our products are sold all over the world. Among them, North America and South America account for 48%, Europe accounts for 26%, Southeast Asia accounts for 15%, and other countries account for 11%. Also, we can make the following custom metal logo plates:

Aluminum screen printed signs, aluminum oil pressure signs, aluminum engraved signs, aluminum anodized signs, aluminum laser engraving signs, aluminum CD texture signs, aluminum embossed-recessed signs, and aluminum brushing signs, etc.

Stainless steel etching plates, stainless steel wire drawing plates, stainless steel sandblasting plates, etc.

Electroformed nickel labels, etc.

Custom metal label of processes

The?custom metal label we produce mainly involve the following common processes:

It has also become a hydraulic process, which mainly refers to the use of liquid to transfer pressure forming to achieve various plastic processing. It is generally used for fine product processing. After cutting the material for this signage, it relies on the hydraulic process to achieve an initial shape-a rectangle with R angles.

Sandblasting process refers to the process of using the impact of high-speed sand flow to clean and roughen the product surface. The golden matte effect shown on the sign in the picture is achieved by this process, which makes the sign look more advanced.

Refers to the metal processing process in which aluminum and its alloys form a layer of oxide film on aluminum products under the corresponding electrolyte and specific process conditions due to the action of the applied current. This process can achieve a variety of colors. The gold shown in the picture sign is finished by the oxidation process, which makes the sign look more colorful.

This process is a method of cutting lines on the surface of the product through mechanical processing. It can cut different grains, generally including straight grain, twill grain, CD grain, and so on. The sign in the picture is a sign craft that combines fingerprints and twill. Make the sign look more textured and glossy.

Generally, signs use 3M adhesive, including 3M9495LE double-sided adhesive, 3M9448A adhesive, 3M467 adhesive, 3M468 adhesive, etc. The adhesives of this brand are relatively strong, and most of them are waterproof. Fire resistance, high-temperature resistance, and other characteristics.

Please initiate your inquiry today

In Huizhou Weihua Technology, we can provide you with a series of optional hardware signs and design schemes, including the material selection of different signs, material thickness selection, material price selection, sign technology selection, sign backing adhesive selection, etc. Our engineering R&D and quality team can ensure to provide you with the most suitable sign technology scheme and high-quality signs for you. Please contact us quickly, our email is wh@chinamark.com, and the contact number is 0086+1992669150.

Read more news

Video:

The main process shows as below

Step 1:St.St. plate

Step 2:Laser cut according to the engineering dwg

Step 3:Film or coating in the dust-free shop, light exposure imaging

Step 4:Etching, ie, remove material by way of chemical reaction or physical corrosion

Step 7:Industry oven, hi-temp, low-temp & constant temp.

Step 5:Get deepened by etching once, and texture finish by twice etching, like snow grain.

Step 8:Professional inspectors and packaging workers

Step 6:Done in the dust-free shop, by professional workers and advanced equipment

Step 9:Applied as precision etched parts for the electronic thin components for the aviation industry, machinery and chemical industry