Custom metal name tags,High end wireless earphone nameplate | WEIHUA

Why choose Huizhou Weihua Technology as badge maker?

Short mold making time and quickly sample produced---

General mold making and completion time only takes 5-12 days, and other difficult molds require 12-28 days. The sample completion time can be completed within 1 to 1.5 days after the mold is completed .

Ultra-low MOQ---

If only required prototype, our company can accept only 5-20 samples, if it is a mass production, we can accept only 500 pcs.

Short delivery time---

General products can be delivered within 2-3 days, and other more complicated products can be delivered within 8-20 days. (Transportation time is not included here)

Convenient and fast transportation method---

we can provide SF Express, Kuayue logistics, UPS, FEDEX, DHL and other express methods, as well as UPS, FEDEX, DHL and other sea and air transportation services

Comprehensive process support---

stamping, forging, aluminum extrusion, CNC, wire drawing, sandblasting anode, silk screen, CD pattern, spraying, polishing, laser engraving, electroforming, electroplating, etc.

High repurchase rate---

Currently, the repurchase rate of old customers has reached 99.98%, and the repurchase rate of new customers has reached 98.5%. The main big-name customers of cooperation include BYD, OPPO, HUAWEI, SONY, JBL, KITCHENAID, ST, DY, etc.

Customers Reviews:

Mr. Zhang---Changping,Dongguan,China

We have been cooperating with Weihua Technology over 7 years. The surface finishing of Weihua products has been treated very well. After assembly, the products are very high-end. The quality of the products has been maintained well and the after-sales service has been handled in a timely manner. , Happy communication, this is the reason why I always choose WeiHua.

Miss Yang-- Longgang,Shenzhen,China

Weihua Technology is our company's top-ranked supplier, ranking among the top 10 suppliers every year. All along, the supply is timely and the product quality is good.

Mr. Chen-Luohu,Shenzhen,China

In general, Weihua is a very good metal sign manufacturer. Compared with other manufacturers in the industry, Weihua is a leader in product technology and surface treatment, and hopes to maintain it and enjoy a happy future cooperation.

Charles-SUWANEE , GA,USA

I am amazed with quality, very fast delivery. Quality is awesome.Happy to work with such a professional team。

Jessica-EL PASO , TX,USA

Love weihua. fast shipping and great quality. Easy to use. Will order more from this seller 。very satisfied with my purchase,

Henry-Berkshire,UK

The Seller was good at communication. Fast and safe delivery.

Items came in looks good.

Kelly-Shatin,HK

Product received as description.Order arrived in time, and numbers and letters are very good quality。Good letters, inside are not empty, completely metal, delivery on time.

Supansa-Samutprakarn,Thailand

Letters are smooth, well polished, real metal, the seller is well done, I recommend, I'm happy. Will continue to order.

Common questions:

A: You can call us directly or send an email to inform, or add our WeChat, whatsapp or skype.

A: Yes, it is included in the price.

A: Not all. It mainly depends on the structure of the signs. Some signs can be finished by other processes without opening the mold, but most of the hardware signs need to be made by opening the mold.

Do you need to order a custom nameplate in any shape? Please contact us as soon as possible, our goal is to always provide you with the highest quality nameplate.

Our high-power laser cutting machine can process any nameplate of standard shapes/materials for you.

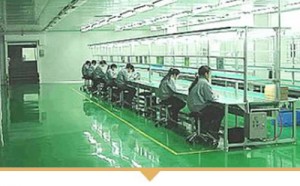

The main process shows as below

Step 1:St.St. plate

Step 2:Laser cut according to the engineering dwg

Step 3:Film or coating in the dust-free shop, light exposure imaging

Step 4:Etching, ie, remove material by way of chemical reaction or physical corrosion

Step 7:Industry oven, hi-temp, low-temp & constant temp.

Step 5:Get deepened by etching once, and texture finish by twice etching, like snow grain.

Step 8:Professional inspectors and packaging workers

Step 6:Done in the dust-free shop, by professional workers and advanced equipment

Step 9:Applied as precision etched parts for the electronic thin components for the aviation industry, machinery and chemical industry