Custom metal nameplates,Suitable for custom speaker nameplate | WEIHUA

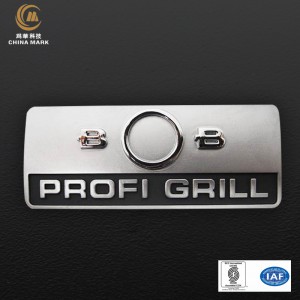

Huizhou Weihua Technology Co., Ltd provides you with the manufacture and design of hardware die-cast aluminum nameplate stickers, high-gloss aluminum nameplates, oxidation signs, stainless steel logos, and the following highlights: Flower signs, also called high-gloss hardware signs.

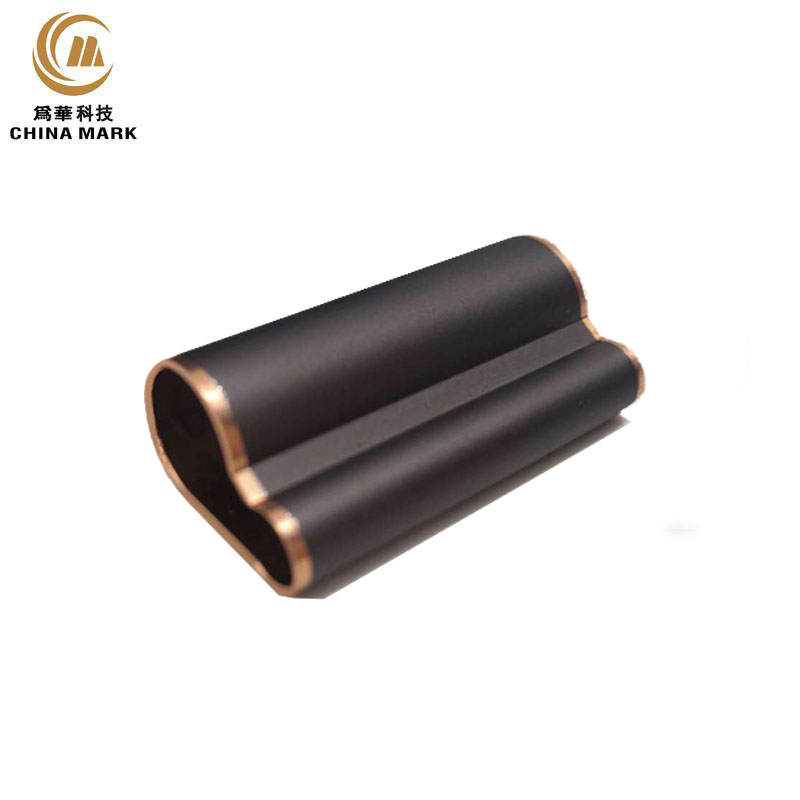

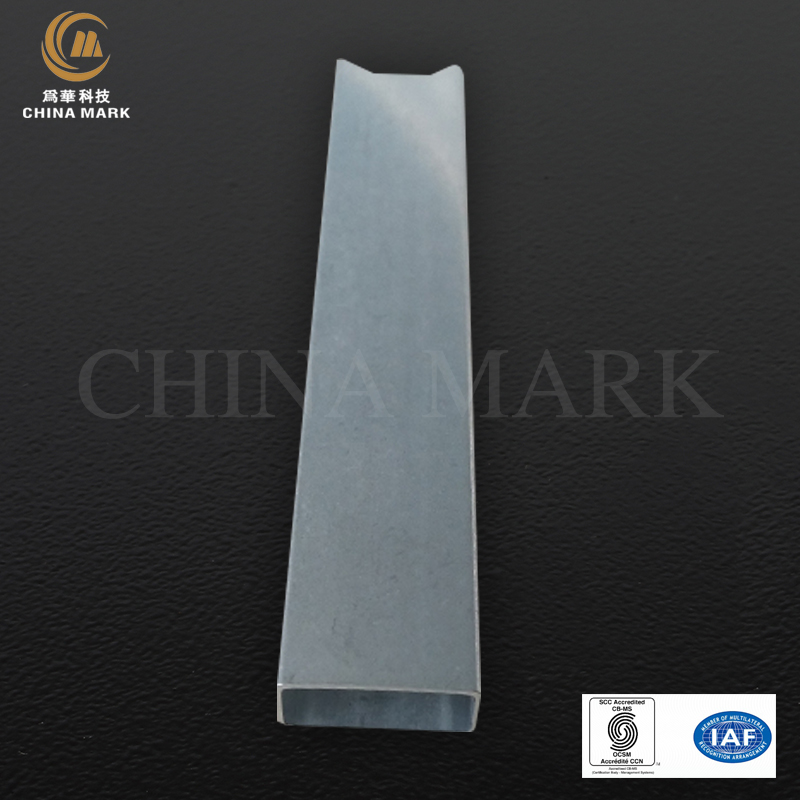

Metal aluminum is generally used as raw material. The thickness is generally 0.3MM to 2.5MM. Common specifications are 1000mm*2000mm, 1200mm*2400mm, 1200mm*3000mm and 1200mm*4000mm

1.Oxidation (such as golden bottom, silver bottom, red bottom, black bottom, etc.)

2.Spray paint: The bottom can be sprayed with different colors of paint according to customer requirements (commonly used colors are sprayed black, red, orange, gray, silver gray, etc.)

3.Paint: The paint must be blocked by a side so that the paint will not flow everywhere, so it requires a frame or the paint place is concave. (The color can also be modified into various colors of paint according to customer requirements)

1.Silk screen: After the product font is highlighted, it is necessary to make different colors on the raised fonts, which can be achieved by silk printing. The fonts on the same plane can be silk-screened in multiple colors. It must be passed through the oven after each color is printed. You can silk-print other colors after baking.

2.Electroplating: After the sign font is highlighted, different colors can be electroplated according to customer requirements (such as: black, gold, red, chrome)

3.Painting (same as the bottom painting method mentioned earlier)

1.High gloss: Use a diamond knife to carve off the paint on the surface of the sign (also known as a batch of flowers, the normal gradient of the grain is 45 degrees, and different grains can be made according to customer requirements, usually with forward twill, reverse twill, and arc , Straight pattern, cd texture, sun pattern, etc.)

2.Sandblasting: At present, many audio products require font sandblasting. This process is more complicated than the above two. After sandblasting the entire sign, it must be oxidized after sandblasting.

1.Make feet behind the label: During this type of installation, there must be two holes for mounting feet on the panel of your product.

2.Adhesive method: The double-sided adhesive is attached directly after the label is produced by us (there are ordinary adhesives, 3m adhesives, Nitto adhesives and other options)

3.Hole punching method: Holes can be punched on the label, which can be directly installed with nails and rivets.

4.Screw up: tap the foot directly behind the label, and then put the screw up. This is mainly used for audio products.

Custom metal sign

Are you looking for high-quality and durable metal nameplates that are not easy to wear and damage? Then, you have found a best supplier-that’s us. We can provide high-quality metal (aluminum, stainless steel or nickel, copper,brass, iron) nameplates. You can design according to your specific needs and provide specific drawings to us. We can help with efficient customization and provide more optimized solutions. .You can choose to use a variety of materials and thicknesses of metal, or you can choose a variety of processes (brushing, polishing, sandblasting, anodizing, CD pattern, printing, etc.) effects.

Weihua Technology is also called China mark?because we are an Guangdong sign manufacturer,with a long history, who specializing in customizing various hardware and plastic signs. We are particularly good at customizing various high-end audio/amplifier nameplates and various high-end kitchenware signs and well-known industrial machinery signs.

Why everyone more inclined to choose Weihua logo?

1. With rich production experience, it belongs to the industry's leading old brand Guangdong sign supplier;

2. Have a professional engineering R&D team with rich experience, who can understand and provide professional signage solutions to meet your customized signage requirements;

3. We have complete and complete production, manufacturing and inspection equipment;

4. Short delivery time, more competitive price;

5. It is deeply loved by customers such as industry brand audio and brand kitchenware, and has repeatedly returned orders, maintaining a cooperative relationship for many years;

6. Provide high-quality pre-sale, in-sale and after-sale service system;

7. OEM/ODM very welcome

Do you need to order a custom nameplate in any shape? Please contact us as soon as possible, our goal is to always provide you with the highest quality nameplate.

Our high-power laser cutting machine can process any nameplate of standard shapes/materials for you.

You may also like

People also ask

The main process shows as below

Step 1:St.St. plate

Step 2:Laser cut according to the engineering dwg

Step 3:Film or coating in the dust-free shop, light exposure imaging

Step 4:Etching, ie, remove material by way of chemical reaction or physical corrosion

Step 7:Industry oven, hi-temp, low-temp & constant temp.

Step 5:Get deepened by etching once, and texture finish by twice etching, like snow grain.

Step 8:Professional inspectors and packaging workers

Step 6:Done in the dust-free shop, by professional workers and advanced equipment

Step 9:Applied as precision etched parts for the electronic thin components for the aviation industry, machinery and chemical industry