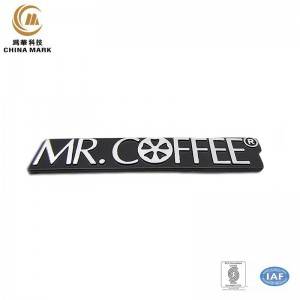

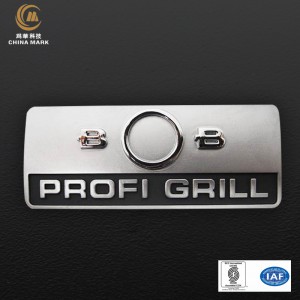

Custom metal nameplates,Trademark nameplate | CHINA MARK

Aluminum nameplate

Aluminum signs refer to signs and nameplate products made of aluminum, which are collectively referred to as aluminum signs.Common custom metal name plates?materials.

Various characters, numbers, patterns, etc. can be printed on the surface.Whether it is aluminum or stainless steel signs or nickel signs, are very beautiful, bright, high hardness, good wear resistance, wide application, large amount of characteristics.Used for industrial machinery, electronic appliances, instruments, meters, household appliances, kitchenware cabinets, daily hardware, daily cosmetics, etc.

Order?Custom Metal Nameplates

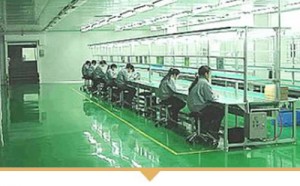

Whether you need to stamp metal signs, metal engraving signs or etched recessed signs, or silk-printed embossed metal logos and other signs, we can do it for you. We have a complete set of hardware sign manufacturing and other equipment, including double-head engraving machine, 12T/16T/25T/300T/600T punching machine, CNC CD pattern machine, fiber laser marking machine, high-gloss wire drawing machine, three-axis Automatic dispensers and CNC machines and other equipment. The signs produced are very delicate and durable.

Introduction and production process

Aluminum badge are one of many signs, usually made of aluminum plate stamping, cutting, embossed and debossed, and aluminum alloy die-casting.

Common chemical treatments for aluminum include chromization, painted, electroplated (silver plated and gold plated), anodized, etched, electrophoresis and other processes. Among them, mechanical processing includes stamping, wire drawing, polishing (mirro surface) spraying, polishing, laser cutting, engraving, laser carving, spraying, printing, silk screen and other processes.

Process example:

The processing materials of metal stamping parts are mainly metal strip materials, such as carbon steel plate, alloy steel plate, spring steel plate, galvanized plate, tin plate, stainless steel plate, copper and copper alloy plate, aluminum and aluminum alloy plate, etc.

Stamping process is a metal processing method. It is based on the plastic deformation of metal. It uses molds and stamping equipment to apply pressure to the sheet to cause plastic deformation or separation of the sheet to obtain a certain shape, size and performance.

Stamping is a processing method with high production efficiency and low material consumption. The stamping process is suitable for the production of larger batches of parts, which is convenient for mechanization and automation

If you need any signs of aluminum, stainless steel and other materials, please contact us. We are a leading manufacturer of hardware signs in Guangdong China.

People also ask:

MATERIAL & FINISH OPTIONS

005" - .125" THICKNESSES

Engraving

Sandblasting

Anodizing(We can reach almost all pantone colors)

Brushing

005" - .125" THICKNESSES

Black

Grey

Clear

Blue

Orange

Red

010" - .012" THICKNESSES

Plating

Painting

Sliver effect

Black effect

010" - .12" THICKNESSES

Mirro effect

Sandblasting

Chemical ecthing

Brushing

Spraying

Learn more about WEIHUA products

The main process shows as below

Step 1:St.St. plate

Step 2:Laser cut according to the engineering dwg

Step 3:Film or coating in the dust-free shop, light exposure imaging

Step 4:Etching, ie, remove material by way of chemical reaction or physical corrosion

Step 7:Industry oven, hi-temp, low-temp & constant temp.

Step 5:Get deepened by etching once, and texture finish by twice etching, like snow grain.

Step 8:Professional inspectors and packaging workers

Step 6:Done in the dust-free shop, by professional workers and advanced equipment

Step 9:Applied as precision etched parts for the electronic thin components for the aviation industry, machinery and chemical industry