Extruded aluminum - neman fasahar weihua [masu samar da kayayyaki na alminium na aluminium] fiye da shekaru 10 na ?warewar kerawa ta musamman. Aluminumaramin ?arancin aluminum, kayan ?arancin zinare na zinariya, tsarin ?arancin ?arancin ?arewa, masana'antun ke ba da tallace-tallace kai tsaye, ?irar samfur, maraba don tuntu?i!

Menene aikin sarrafa kayan ?arfe na wayar hannu na ?arfe?

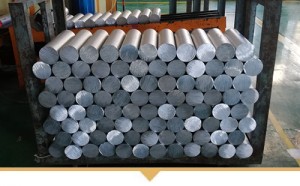

1. Aluminum extrusion

Mataki na farko shine yankewa tare da fitar da aluminium na silinda, wani tsari wanda akafi sani da extrusion na aluminium, wanda yake sanya aluminin da aka fitar a cikin takardar 10mm wanda yake da sau?in aiwatarwa kuma yayi yawa da kuma wahala.wannan shine aikin da yake bu?atar aikin sarrafa kayan extrusion.

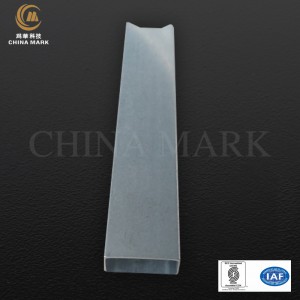

2. DDG

An yi amfani da kayan aikin inji na CNC (cibiyar hawan mai sauri da buga tapping) don daidaita allon aluminum din cikin sifa mai girman uku na 152.2 × 86.1 × 10mm ta hanyar DDG don sau?a?e ?arshen CNC na gaba. Wannan aikin yana farawa tare da amfani da kayan aikin carbide don aiki.CNC carbide kayan aiki

3. Mugu da nika cikin kogon ciki

Don sau?a?e aikin inji na CNC, jikin ?arfe yana ?aure da bangon katako.Rashin ba?in ciki mai ?yalli na ciki, ramin ciki, da ginshi?in sakawa ha?e tare da aikin tsayarwa, wanda yake da mahimmanci ga maha?in sarrafa mai zuwa.

4. Milling ramukan eriya

Ga dukkan wayoyin hannu, matsalar mafi wahalar warwarewa ita ce matsalar sigina, wanda kuma ya samo asali ne daga mummunan sigina da ?arfe ya haifar lokacin da aka fara amfani da iPhone 4. Aluminium kuma yana toshe (ya raunana) siginar mitar rediyon wayar, don haka dole ne a rabe shi don siginar na iya samun hanyar shiga da fita.Saboda haka, yin gyaran eriya shine mafi mahimmanci, mataki mafi wahala, dole ne eriyar eriya ta zama daidai, kuma su kula da hanyoyin ha?in da suka dace don tabbatar da ?arfi da mutuncin kwasfa na ?arfe.

5. T rikewa

Bayan nika ramukan eriya, ana amfani da "magani na T" don kula da aluminiya zuwa wani farfajiya wanda za'a iya hada shi da robobi na injiniya.Yana bukatar sanya jikin karfe a cikin wani wakilin sinadarai na musamman, kamar ruwa na T, don samar da nanoscale (1 nanometer = 10 ^ -9 mita) ramuka a saman aluminiya, a shirye shiryen allurar nanoscale na gaba.

6.NMT Nano allura gyare-gyaren

A "allura gyare-gyaren" tsari damar da NMT Nano allura gyare-gyaren aiwatar da za a aiwatar saboda na karfe jiki bi da T.NMT Nano allura gyare-gyaren ne zuwa matsi da roba na musamman a karkashin babban zazzabi da kuma babban matsa lamba a cikin karfe abu bayan T magani, don haka cewa filastik da saman karfe na nanoscale kananan ramuka sun hade sosai, don cimma manufar matse eriya.

7. Gama nika dutsen cambered

Ga wayoyin hannu duka ?arfe, banda eriya na sigina, akwai tsarin 3D na jikin ?arfe, wanda ya zama aiki mafi ?aukar lokaci, yana ?aukar sama da da?i?a 1,000.

8. Gama nika gefe

Abokai na hankali zasu iya lura cewa 3D ?in ?arfe mai ?wan?wasa na jikin ?arfe yana ta yin ta?ar iska ta hanyar CNC, amma har yanzu akwai sauran larurar rashin aiki a gefen gefen, wanda ke bu?atar daidaitaccen gefen gefen, sannan kuma kuna iya ganin samfurin ?arfe harsashi.

9. Goge goge

Kafin amfani da kayan aikin injina na CNC mai saurin gaske, amma kuma zai iya cimma nasarar kammala aji A1 ~ A2, don biyan bu?atun sarrafawa na gaba, ana bu?atar a goge shi zuwa kammala A0 aji, na iya zama tasirin madubi.

10. Sandblasting

Koyaya, wayar duk ?arfe ba ta da cikakken haske, amma tana gabatar da yanayin daskarewa. Wannan yana bu?atar tsarin "sandblasting" don magance ?arfe zuwa tasirin sanyi.

11. Anode daya

Gami na Aluminium yana da kwari sosai, don kada abubuwan waje kamar su zufa su dame shi, dole ne a sanya masa anodized Hakanan kuma aikin canza launin waya ne, wanda ke canza launin alminiyon zuwa zinare ta hanyar maye gurbin yana da matukar wahalar sarrafawa aiwatar da rini mai gami na alumini, bambancin launi, tabo zai bayyana idan sarrafawar ba kyau, wanda kuma zai rage yawan amfanin ?asa.

12. Haskaka magani

Tsarin yankan gefen baki mai haske yana bu?atar yankan sassa ta amfani da mafi girman darajar injunan CNC mai saurin gaske, aikin da aka sani da hakowa ko nunawa.

13. isharshen milling cikin ramin ciki

Bayan matakai 12 na aiki, kwasfa na ?arfe ya fara ganin bayyanar, sannan za'a yi amfani da shi don ?ora shafi na sanya makullin kullewa da sauran abubuwan da suka wuce gona da iri da aka cire, bari ?wanfen ?arfe a ciki tsaftatacce.

14. Secondary anode

Harsashin, wanda aka sarrafa ta CNC, yana bu?atar magani na biyu na anodic don sanya iskar shaka a fili kuma ya samar da fim mai ?imbin yawa da wuya, wanda hakan ya sa ya zama mai saurin lalacewa kuma ba mai sau?in tabo ba.

15. Milling conductive din kadan

Bayan anodic oxidation na aluminum alloy shell mai tasirin sakamako zai zama mafi muni, don haka ya zama dole a cire fim din anodic oxidation na gida, karfe da aka fallasa don samun kyakkyawan sakamako na ?asa, kuma ana bu?atar wucewa ta hanyar bitar sarrafawar bit na aikin CNC.

16.Ya narke goro

A ?arshe, an saka goro a cikin filastik ?in da aka gama tare da hannun mutum-mutumi don tabbatar da ha?uwar makullin wayar a nan gaba.

?