Menene aikin sarrafa kayan ?arfe?

Extarawar ?arfesarrafawa hanya ce mai mahimmanci don sarrafa matsa lamba ta amfani da ?a'idar ?arfen filastik. Ana sarrafa ?ananan ?wayoyi a cikin bututu, sanduna, mai siffa T, mai siffa ta L da sauran bayanan martaba a wani lokaci ta hanyar extrusion.

Extarfin goge ?arfe shine mafi mahimman kayan aiki don fahimtar sarrafa kayan ?era ?arfe Extrusion yana ?aya daga cikin manyan hanyoyin samar da ba?in ?arfe da ba?in ?arfe da kayan bakin ?arfe da ?ir?irawa da sarrafa sassan.

Hakanan hanya ce mai mahimmanci don shirye-shiryen da sarrafa abubuwan ci gaba kamar abubuwa da yawa wa?anda aka ha?a da kayan foda.

Daga zafi extrusion na manyan-karfe karfe ingots, zafi extrusion na babban bututu da sanda bayanan martaba zuwa sanyi extrusion na kananan daidaici sassa, kai tsaye solidification da kuma molding na hadedde kayan daga foda da pellets zuwa intermetallic mahadi, Don wahalar-to- kayan sarrafa abubuwa kamar su superconducting materials, ana amfani da fasahar extrusion ta zamani.

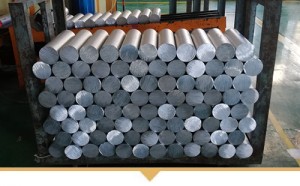

Rarrabaccen nau'in aluminum

Dangane da shugabancin kwararar filastik na karfe, za'a iya raba extrusion zuwa nau'ikan masu zuwa:

Gaskiya mai kyau:

A yayin samarwa, alkiblar kwararar karfe daidai take da na naushi

Baya extrusion:

A yayin samarwa, alkiblar kwararar karfe ya saba da na naushi

Extungiyar extrusion:

A yayin samarwa, shugabancin kwararar wani bangare na mara daidai yake da na naushi, dayan bangaren kuma na karfe yana gudana ta kishiyar naushin.

Radial extrusion:

A yayin samarwa, alkiblar kwararar karfe ta kai digiri 90 zuwa shugabancin motsi na naushi.