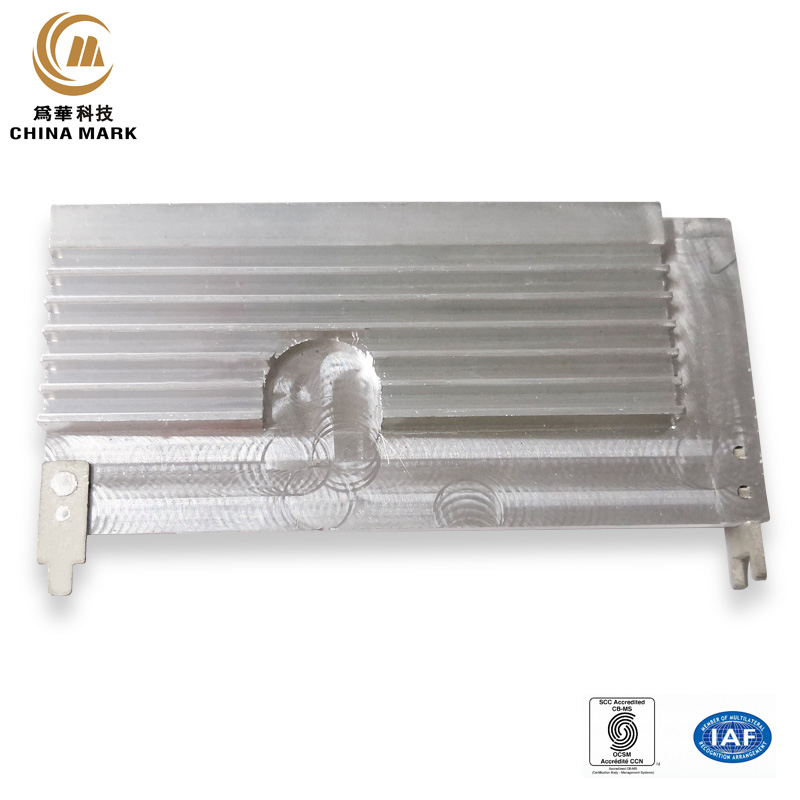

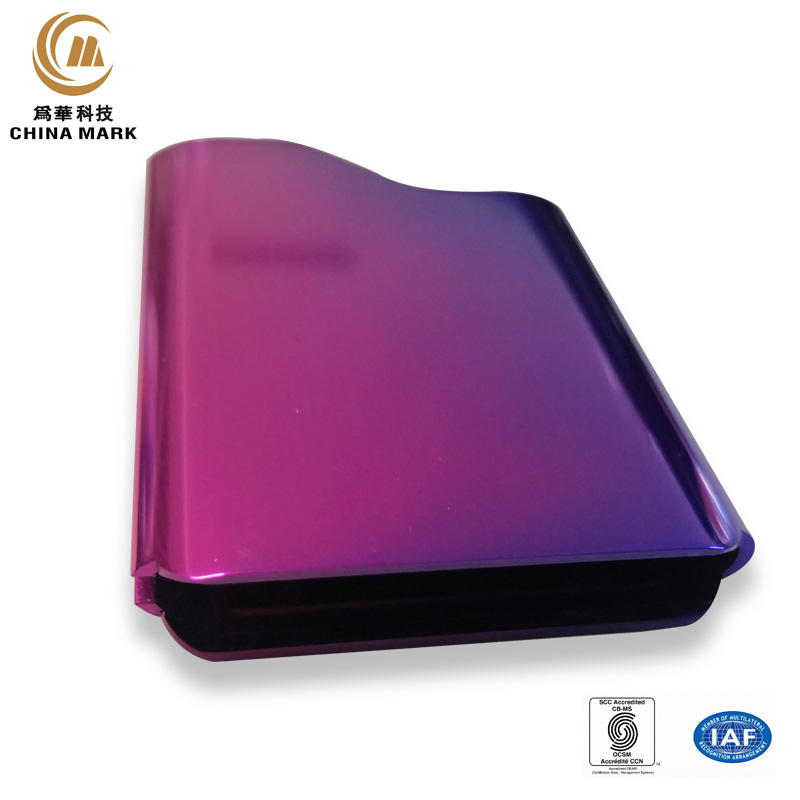

Aluminum extrusion: Shin aikin ha?in gwal na almara (nakasawa) ingot extrusion gyare-gyaren tsari tare da mai fitarwa.

Fasahar Allon gami ta Aluminiya

Rarraba sassan sassa:

Sashe mai ?arfi: babu ramuka a cikin sashin.

Hollow profile: ?angaren bayanan martaba yana da ramuka.

Tsarin da zane na sauki extrusion mutu:

Tubba guda extrusion ya mutu akwai guda biyu: na farko shine ingantaccen extrusion mutu na biyu shine m profile extrusion die.The takamaiman tsarin shine kamar haka:

1) ganga mai yaduwa: jiki mai silinda mai launuka da yawa wanda aka yi shi da ?arfe mai ?arfi mai ?arfi, wanda za a iya saukar dashi tare da rufin ciki. An ?addara tsawon ne gwargwadon ?ararrakin kayan.

2) tallafin tallafi: tabbatar da cewa kayan kwalliyar da kushin sunada hankali, shine a shigar da kayan kwalliyar, kayan kwalliyar karin kayan taimako.

3) die pad: the die pad and the die have the same size, da kauri ne sau 3 na mutu kauri, kuma kai da extrusion matsa lamba tare da die.Die pad, mutu rami size ne dan kadan ya fi girma da mold. : kayan aikin gami

4) latsa bakin: kayan aikin taimako wa?anda ke tabbatar da cewa ?irar ba ta canzawa yayin ?arna kuma suna dacewa sosai da ganga mai extrusion. An tsara tsari da girman gwargwadon nauyin mai fitarwar.

5) gasket extrusion: kayan aikin taimako don hana ha?uwa kai tsaye tsakanin mashin extrusion da ?arfe da aka fitar.sai diamita na waje yayi ?an?ani da diamita na ciki na ganga mai ?wan?wasa, kuma kaurinsa yana tsakanin 40 mm da 150mm.

6) ?wan?olin ?wan?wasa: lokacin da ?wan?olin ?wan?wasa ke aiki, yana shiga cikin silinda na extrusion da lambobin sadarwa tare da takalmin extrusion. Bearingaukewar ?wan?wasa ya kasance cikin matsakaicin matsin lamba na mai fitar da kayan.Material: 3Cr2W8V.

Mutu ka'idar sanyi rami:

Tsarin rami mai ra?a??en bayanin rami ?aya ra?a??en tsari: gaba?aya shine sanya cibiyar ?irar jujjuyawar da cibiyar ?ira ta zama daidai.Idan bangon kaurin ya banbanta sosai, yakamata a shirya ?angaren mafi bakin ciki a tsakiyar ginin.

Porous profile die rami sanyi: don karamin sashi ko sashin daidaito ba shi da kyau, yawanci ana amfani da shi mai ra?umi.

Tabbatar da bel mai aiki mai rami:

1) ?auki ?ayan ?angaren azaman ma'auni, inda tsayin aikin yake (sau 1.5 zuwa 2) na ?arancin samfurin da aka gama.

2) tsawon aikin da yake makwabtaka da inda ake nuni shine tsawon aikin da yake aiki a wurin da aka hada shi da 1mm.

3) tare da kauri iri ?aya, tsayin aikin tsayi a daidai nesa daga tsakiyar ma?erin ?in ?aya ne.

4) farawa daga tsakiyar sifar, ?ira da raguwar tsiri na aiki na kowane nesa na 10mm ana iya komawa zuwa adabin da ya dace.

5) wukake marasa amfani a cikin bel din aiki: wukake wukake da yawa zasu raunana karfin bel din aiki.

Block Angle:

Lokacin da tsayin rami mai mutu?ar aiki ya fi 15 zuwa 25mm, a zahiri, ?arfen ba shi da dacewa da tsiri mai aiki saboda ?an?antar girma, a wannan lokacin, ana iya daidaita ?imar ?arfe ta Hanyar toshewa. Angle tsakanin busbar da layin tsakiyar extrusion na bel mai aiki shine Angle mai toshewa, kuma mafi ingancin toshe Angle shine digiri 3 zuwa 5.

Mala'ikan Gudun Ruwa: gaba?aya, Hannun gudana yana da mazugi mai daidaituwa ko mazugi mai jujjuya kan fuskar ?arshen fuskar fasalin.

Abinda ke sama shine game da menene extrusion na aluminium da kayan fasahar kera kayan aikin almara; Mu masu sana'a ne aluminum extrusion ?iren ?arya masana'antu, na iya samar da: arc aluminum extrusion, triangle aluminum extrusion da sauran ayyukan sarrafawa na musamman; Maraba da tuntu?ar ~

Post lokaci: Apr-11-2020