Daidaici machining shine aiwatar da cire abu daga kayan aiki yayin kammalawa wanda ke kula da juriya mai kusanci.Wannan akwai nau'ikan nau'ikan madaidaicin madaidaici, ciki har da milling, juyawa da fitarwa.

Ingantaccen aikin daidaiton aiki yana bu?atar ikon bin takamaiman takaddun zane wa?anda aka kirkira ta hanyar taimakon komputa (CAD) ko shirye-shiryen samar da komputa (CAM) .Wannan fasahar ta inji ta CNC na iya ?ir?irar sigogi 3D ko Shaci don samar da injuna, abubuwa ko kayan aiki dole ne a tsara shi don tabbatar da inganci da nasara.

Daidaitaccen kayan inji zai iya amfani da abubuwa iri-iri, kamar tagulla, gilashi, hoto, filastik, ?arfe da sauran karafa.Da ya danganta da girman aikin da kayan da abin ya ?unsa, za a yi amfani da nau'ikan kayan aikin ?era ?ira da fasaha. masu aikin injiniya na daidaito dole ne su kasance masu ?warewa da ?warewa a cikin wa?annan matakai daban-daban da kayan aiki.Zasu iya amfani da kowane ha?in injunan hakowa, injin nika, lathes, injin ni?a, saws har ma da mutum-mutumi masu saurin aiki don yin aikin.

Abubuwan da aka yi amfani da su a cikin CNC:

Gilashin Titanium (Ti - 6 al4v)

Matrix Matrix Composites MMC (AMC225xe)

Steels na Musamman (300 m, Maraging 300-350, 15 cdv6, 17-4 PH da sauransu)

Gilashin Aluminium (2014, 2024, 6082, 7050, 7075 da sauransu), karfe da Copper

Superalloys (Inconel 625 da 718)

Iri kayayyakin daidaici:

1. Samfura da zane na musamman

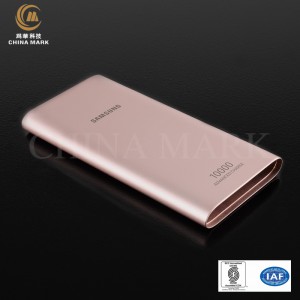

2. Kayan lantarki

3. Lokaci daya kuma ba likitan magani ba

4, sadarwa,

5. Masana'antu da OEM

6. braarfafa sashi, tsayayyen na'urar, daidaitaccen ?angaren, harsashi da ?angaren, strut da tsarin tsari duk samfuran gama gari ne wa?anda masana'antar CNC ta musamman ta samar.

Game da mu daidaici CNC machining sabis

Babban fa'idodi na daidaitaccen ?irar CNC sun ha?a da ikon ?ir?irar sassa masu ha?ari tare da madaidaiciyar madaidaiciya yayin ri?e ?ananan samarwa da farashin shigarwa.

Injin CNC shine ingantaccen kuma ingantaccen fasaha wanda yake kawar da yiwuwar kuskuren ?an adam kuma don haka yana taimakawa inganta ?imar gaba ?aya. Bugu da ?ari, ta hanyar ba da lokaci ga masu aiki yayin samfuran, ana iya mai da hankali kan tabbaci mai kyau da kuma ba da kulawa na aikin, wanda yana taimakawa tabbatar da cewa an cika cikakkun bu?atun aikin samarwa.

Dangane da ragin farashi, inginan CNC ba kawai yana rage farashin ta hanyar rage bu?ata ga ?wararrun ma'aikata ba, amma kuma yana rage jimlar kayan da aka ?ata.

Cikakken daidaito CNC machining

Muna ba da cikakkun sabis na injina na CNC don duk abin da kake da shi daidai, lathes, mutu nutsewa, ?aramin hakowa da kuma bu?atun gaba ?aya.Mayanin injiniyoyinmu suna amfani da sabon ?irar CAD / CAM da fasaha don aiki hannu tare da abokan cinikinmu.

Kwamfuta ya taimaka zane da masana'antu

Muna ha?akawa koyaushe da saka hannun jari a cikin fasaharmu da kayan aikinmu don bawa injiniyoyinmu damar tsara hadadden aiki don biyan bu?atu mafi bu?ata.Mu injiniyoyinmu suna sanye da samfurin 3D da kuma hanyoyin CAD / CAM wa?anda ke ba mu damar kawo cikakkun sakamako.

Kuna iya dogara da inganci

Muna darajar inganci.Muna da himma don samar da samfuran da ayyuka wa?anda suka ha?u ko suka wuce tsammanin abokin ciniki.Kullum muna neman hanyoyin inganta tsarin gudanar da ingancinmu.

Kodayake mafi yawa CNC daidaici machining ya dace da sarrafa ?arfe, wa?annan kayan aikin suna da yawa sosai kuma ana iya amfani dasu don samar da ke?a??u daidaito sassa ga masana'antu iri-iri.Barka da zuwa yi mana nasiha