?O ka aluminika extruded - ke ?imi nei i ka ?enehana weihua [nā mea ho?olako extrusion extrusion alumini] ?oi aku ma mua o 10 mau makahiki o ka hana i hana pilikino ?ia. ?O ka extrusion alumini li?ili?i, extrusion alumini gula, kahi hana extrusion ki?eki?e loa, nā mea kū?ai pololei i nā kū?ai, kūlana huahana, ?olu?olu e kūkākūkā!

He aha ke ka?ina hana a nā kelepona aluminika kelepona pa?a lima?

1. Aluminium extrusion

?O ka hana mua e ?oki a ho?oku?u i ka aluminika paukū, kahi hana i ?ike ?ia ?o ka extrusion alumini, kahi e hana ai i ka alumini extruded i kahi pepa 10mm e ma?alahi e hana a ?oi aku ka pa?akikī. ?O kēia ka hana e pono ai ka extrusion puna hana.

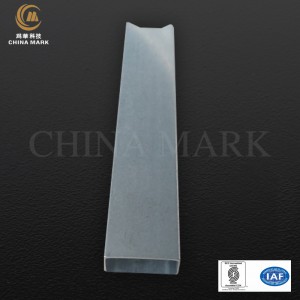

2. Ka DDG

Ho?ohana ?ia ka mīkini mīkini CNC (ke kalai wikiwiki ?ana a me ke kikowaena kikoo) e wili pono ai i ka pepa alumini i kahi nui ?ekolu dimensional o 152.2 × 86.1 × 10mm ma o DDG e kōkua ai i ka ho?opau ?ana o CNC ma hope. Ho?omaka kēia hana me ka ho?ohana ?ana i nā mea hana carbide e hana.CNC carbide mea hana

3. ?O ka wili palaoa ?ana i ka lua o loko

I mea e ho?oma?ama?a ai i ka mīkini ?ana o CNC, ho?opa?a ?ia ke kino metala e ka pa?a o ka paia. ?O ka wili palaoa o loko, ?o ka lua o loko, a me ke kolamu ho?onohonoho i hui pū ?ia me ka hana lima, a he mea nui ia i ka loulou o ka hana ma hope.

4. Nā slot kukuna wili

No nā kelepona metala a pau, ?o ka pilikia pa?akikī e ho?oponopono i ka pilikia hō?ailona, ??a ua hopena ?ia e ka hō?ailona maika?i ?ole i ho?okumu ?ia e ka mea hao i ka wā i ho?omaka mua ?ia ai ka iPhone 4. Pale pū ka ?Amelinum (ho?onāwaliwali) i ka hō?ailona pinepine lekiō o ke kelepona, no laila pono ia e slotted i hiki i ka hō?ailona ke loa?a i kahi ala i loko a ma waho. No laila, ?o ka wili ?ana i ka slot antenna ka mea nui loa, ka ?anu?u pa?akikī loa, pono e wili kaulike ka antenna slot, a mālama i nā kiko loulou kūpono e hō?oia i ka ka ikaika a me ke kūpa?a o ka leho hao

5. T lawelawe

Ma hope o ka wili ?ana i nā kau antenna, ho?ohana ?ia ka "lapa?au T" e mālama ai i ka alumini i kahi papa i hiki ke ho?ohui ?ia me nā plastics ?enekini. Pono e ho?okomo ?ia ke kino metala i kahi ?enekini kemika kūikawā, e like me ka wai T, e hana nanoscale (1 nanometer = 10 ^ -9 mau mika) puka ma ka ?ili o ka aluminika, i ka ho?omākaukau ?ana no ka pahu kui nanoscale hou a?e.

6.NMT nano ka pahu kui mōlina

Hā?awi ke ka?ina hana "injection injection" i ke ka?ina hana ho?ohehe?e nano NMT ma muli o ke kino metala i mālama ?ia e T.NMT nano injection ho?ohehe?e e ?omi i ka plastic kūikawā ma lalo o ke ki?eki?e wela a me ke kaomi ki?eki?e i nā mea hao ma hope o ka ho?oma?ama?a ?ana o T, no laila i ka ea a me ka hao o ka nanoscale puka li?ili?i i ho?ohui pa?a ?ia, i mea e ho?okō ai i ke kumu o ka ho?opa?a ?ana i ka antenna.

7. E ho?opau i ka milling milling ?ili

No nā kelepona metala āpau, me ka ho?ohui i ka antenna hō?ailona, ??aia ka 3D e hana ana i ke kino metala, ?o ia ka hana nui o ka manawa, e lawe ana ma mua o 1,000 kekona.

8. E ho?opau i ka ?ao?ao wili

E ?ike paha nā hoa aloha e pili ana ka 3D cambered ?āpana o ke kino kila e ka milling e CNC, akā aia nō kahi pō?ai o ka redundancy a puni ka lihi, e koi ana i ka wili pono ?ana o ka ?ao?ao, a laila hiki iā ?oe ke ?ike i ka prototype o ka hao. pūpū.

9. Polohi

Ma mua o ka ho?ohana ?ana o nā meahana mīkini ki?eki?e-ki?eki?e ki?eki?e ki?eki?e loa, akā hiki wale nō ke ho?okō i ka ho?opau papa A1 ~ A2, e ho?okō i nā koina hana e hiki mai ana, pono e ho?onani ?ia i ka pau ?ana o ka papa A0, hiki ke lilo i aniani hopena.

10. Kahunaone

Eia nō na?e, ?a?ohe hopena gloss piha o ke kelepona metala a pau, akā hā?awi i kahi papa hau. Pono kēia i kahi hana "one" e mālama i ka mea hao i kahi hopena hau.

11. Ho?okahi anode

Kūle?a pa?a ke alumini alumini, i mea e ho?ohaunaele ?ole ?ia e nā mea kūwaho e like me ka hou, pono ia e anodized. ?O ia nō ke ka?ina o ke kala ?ana i ke kelepona, e ho?ololi ana i ke kala alumini i ke gula ma o ka anodizing. He pa?akikī loa e kaohi i ka ke ka?ina hana o ka pena ?ana i ke kinikini alumini, ?oko?a kala, ?ike ?ia nā kiko inā maika?i ?ole ke kaohi, kahi e hō?emi ai ho?i i ka hua.

12. Hō?ike ko?iko?i

Pono ka ho?olālā ?oki aniani e ?oki i nā kihi me ka ho?ohana ?ana i ka papa ki?eki?e o nā mīkini ?oi loa-ki?eki?e ?o CNC, kahi hana i kapa ?ia ?o ke ?eli ?ana a i ?ole ke kahalaha ?ana.

13. E ho?opau i ka wili ?ana i ka lua o loko

Ma hope o nā ka?ina he 12 o ka hana ?ana, ua ho?omaka ka iwi hao e ?ike i ka helehelena, a laila e ho?ohana ?ia e ho?opa?a i nā kolamu ho?onohonoho laka a me nā mea ?oi aku i ho?one?e ?ia, e waiho i ka iwi metala i loko o ka ma?ema?e.

14. Pualua anode

?O ka pūpū, i hana ?ia e CNC, pono i ka lua o ka anodic lapa?au e oxidize i ka ?ili a hana i kahi ki?i ?oni?oni pa?akikī a pa?akikī ho?i, e ?oi aku ka pale a me ka ma?alahi ?ole o ka stain.

15. Ke wili nei i ka bit conductive

Ma hope o ka anodic oxidation o ke alumini alloy shell conductive hopena e lilo i mea ?ino loa, no laila he mea pono e hemo i ke ki?i ?oni?oni anodic kūloko, metala i hō?ike ?ia e ki?i ai i kahi hopena maika?i maika?i, pono pū kekahi e hele i waena o kahi wili conductive o ka hana ?ana a CNC.

16. Nut melt ho?ohehe?e

?O ka mea hope loa, ua ho?okomo ?ia ka nati ?aha i loko o ka plastic i ho?opau ?ia me ka lima robotic e hō?oia i ka hui ?ana o nā pā alumini o ke kelepona.

?