Ke ka?ina hana extrusion alumini

Ho?omaka maoli ke ka?ina hana extrusion alloy me ka ho?olālā huahana, no ka mea, ho?okumu ?ia ka ho?olālā huahana i nā koina ho?ohana i hā?awi ?ia, kahi e ho?oholo ai i nā palena hope loa o ka huahana. E like me ka hana ?ana o ka mīkini me ka hana, ka hana lapa?au i luna a me ka ho?ohana ?ana i nā koi o ka nohona. , kēia mau waiwai a me nā koi e ho?oholo maoli i ke koho ?ana o ka aluminika extruded.

Eia nō na?e, ho?oholo ?ia nā waiwai o ka aluminium extruded e ka ho?olālā hi?ohi?ona o ka huahana. ?O ke kinona o ka huahana e ho?oholo i ke ?ano o ka extrusion die.

I ka manawa e ho?onā i ka pilikia ho?olālā, ho?omaka ke ka?ina hana extrusion hiki ke ho?olei i ke ko?oko?o aluminika, pono e wela ka lā?au ho?ohehe?e alumini ma mua o ka extrusion e ho?opalupalu iā ia, ho?okomo ?ia ka ho?omehana alumini maika?i sheng ingot i loko o ka pahu extruder i loko, a laila ki?eki?e. mana paukū?oloka?a pahu pahu extrusion ko?oko?o, ka mua o ka extrusion ko?oko?o i ka pu?e pale, e like me ka wela pahee aluminika oka a ma dummy palaka ma lalo ikaika pu?e mai punahelu miomio mōlina extrusion mōlina.

?O kēia ka mo?a no: ke ?ano o ka huahana e pono ai no ka hana.

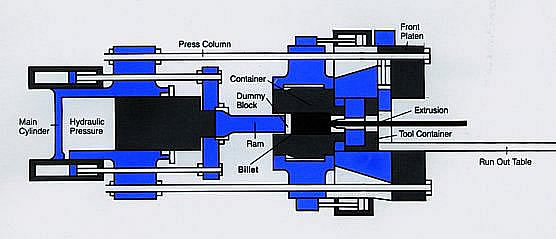

?O ke ki?i: ?ano ho?ohālikelike ākea hydraulic extruder diagram diagram

?O ka ?ao?ao o ka extrusion waiho ?ia i ka ?ākau

He wehewehe ma?alahi kēia o ka extrusion pololei i ho?ohana nui ?ia i kēia lā. ?O ka extrusion Indirect kahi hana like, akā aia kekahi mau ?oko?a ko?iko?i nui.

I ke ka?ina hana extrusion. Ho?okomo ?ia ka mea make ma ka pā hollow extrusion, no laila ua kaomi ?ia ka make i kahi pā ?a?a ?ole e ne?e ana, e koi ana i ke kinikini aluminika e hele i mua i ka pā hollow extrusion ma o ka make.

I ka ?oia?i?o, ua like ka hana extrusion me ka ?omi ?ana i ka nīpala niho. Ke ho?opili ?ia ke kaomi i ka hopena pa?a o ka ?āpiki niho, kaomi ?ia ka toothpaste cylindrical ma o ka puka ākea.

Inā pālahalaha ka hāmama, puka ka niho niho i ?omi ?ia me he lipine lā.

?Oia?i?o, hiki ke ?omi ?ia i nā kinona pa?akikī i ka puka o ke ?ano like. Eia kekahi la?ana, ho?ohana nā mea hana keke i nā paipu i ho?ohālikelike ?ia e kaomi i ka ?aikalima e hana i nā ?ano frills āpau.

?Oiai ?a?ole hiki iā ?oe ke hana i nā huahana pono he nui me ka toothpaste a i ?ole ka ?aikalima, ?a?ole hiki iā ?oe ke kaomi i ka aluminika i loko o nā paipu me kou mau manamana lima.

Akā hiki iā ?oe ke ho?ohana i kahi kaomi uila ikaika e ho?oku?u i ka alumini mai kahi ?ano i hā?awi ?ia no ka hana ?ana i nā huahana pono like ?ole o kēlā me kēia ?ano.

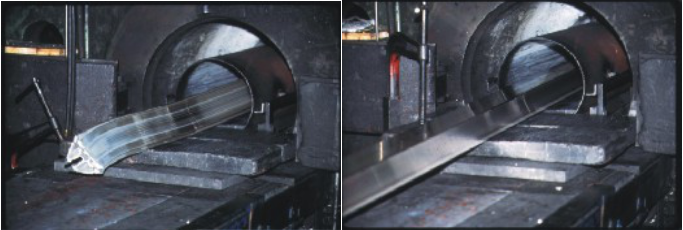

?O ke ki?i ma lalo (hema) hō?ike i ka ?āpana mua o ka extruder i ka ho?omaka o extrusion. (akau)

?O ka pā

?O ka pā alumini ka hakahaka o ke ka?ina extrusion. ?O ka ?aukā aluminika i ho?ohana ?ia no ka extrusion hiki ke pa?a a hollow paha, pinepine ka paukū?oloka?a, a ho?oholo ?ia kona lō?ihi e ka extrusion tube.

Ho?okumu pinepine ?ia nā ko?oko?o aluminium e ka ho?olei ?ana, a i ?ole ka pā ?ana ?ana a i ?ole ka paukū paina. Hana ?ia ia e ke kani ?ana i nā kaola hao aluminika me nā mea ho?ohui maika?i.

Hana pinepine ?ia nā mea ho?opili alumini i nā mea metala ?oi aku ma mua o ho?okahi. Hana ?ia nā mea ho?opili alumini extruded i ke kumumana?o (?o ka ma?amau ma mua o 5%) nā mea (e like me ke keleawe, magnesium, silikone, manganese, a zinc) e ho?omaika?i i nā waiwai o ka alumini ma?ema?e a ho?opili i ke ka?ina extrusion.

Ho?ololi ka lō?ihi o ke ko?oko?o alumini mai ka mea hana i ka mea hana, i ho?oholo ?ia e ka lō?ihi i makemake ?ia, ka lākiō extrusion, ka lō?ihi ho?oku?u a me ka ?ae extrusion.

Loa?a nā lō?ihi ma?amau mai 26 ?īniha (660mm) a 72 ?īniha (1830mm). Ma waho o nā anawaena mai 3 ?īniha (76mm) a 33 ?īniha (838mm), 6 ?īniha (155 mm) a 9 ?īniha (228 mm).

?Naehana extrusion pololei

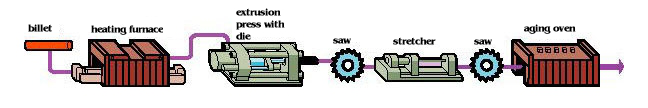

[billet] [ho?omehana ho?omehana] [extrusion press with die] i ?ike ?ia [strecher] [?elemakule overn]

Hō?ike ke ki?ikuhi i nā ?anu?u ma?amau o ka extruding i kahi pā alumini

?

Ke ho?oholo ?ia ke kinona huahana hope loa, koho ?ia ke kinikini aluminika kūpono, ho?opau ?ia ka hana make extrusion, a ho?opau ?ia ka ho?omākaukau no ke ka?ina extrusion maoli.

A laila preheat i ka pā alumini a me ka mea hana extrusion. I ka wā o ka extrusion process, pa?a ka pa aluminika, akā palupalu i ka umu ahi.

?O ke kiko ho?ohehe?e o ke kinikini aluminika e pili ana iā 660 ℃. ?O ka mahana ho?omehana ma?amau o ke ka?ina extrusion ?oi aku ka nui ma mua o 375 ℃ a hiki ke ki?eki?e iā 500 ℃, kauka?i ?ia i ke ?ano extrusion o ka metala.

Ho?omaka ka papa hana extrusion maoli ke ho?omaka ka lā?au extrusion e ho?opili i ke kaomi i ke ko?oko?o alumini i ka ingot.

Ho?olālā ?ia nā kaomi uila like ?ole e kaomi ma nā wahi āpau mai 100 mau tona a i 15,000 mau tona. Ho?oholo kēia kaomi extrusion i ka nui o ka extrusion i hana ?ia e ka mīkini extrusion.

Hō?ike ?ia nā kiko?ī huahana extruded e ka nui o ka nui o ke ke?a o ka huahana, i kekahi manawa ho?i e ke anawaena o ka huahana.

Ke ho?omaka nei ka extrusion, ua ho?okau ?ia ka pa ?aila i ka hopena o ka hopena a lilo i pōkole a mānoanoa, a hiki i ka ho?onui ?ia ?ana o ka ?aukā alumini e ka paia ingot barela;

A laila, ke pi?i mau nei ke kaomi, ?a?ohe wahi e kahe ai ka mea palupalu (pa?a mau) a ho?omaka ?ia e ?ūlū ?ia mai ka puka o ka hopena i kahi hopena ?ē a?e o ka popopo, e hana ana i ka ?ikepili.

Ma kahi o 10% o ke ko?oko?o alumini (me ka ?ili ko?oko?o aluminika) i waiho ?ia i ka pahu ingot, ?oki?oki ?ia ka huahana extrusion mai ka punahelu, a ho?oma?ema?e a hana hou ?ia nā mea hao i koe i ka pahu ingot. Ma hope o ka ha?alele ?ana o ka huahana i ka punahelu, ?o ke ka?ina o hope ka mea e kinai ka mīkini huahana extrusion wela, mīkini a ?elemakule.

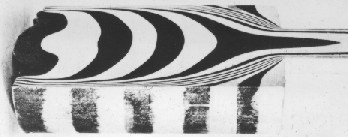

Ke ho?oku?u ?ia ka aluminika wela mai ka punahelu ma o ka ingot cylinder, ?o ka mea hao i waenakonu o ka ?aukā alumini e kahe wikiwiki a?e ma mua o ka lihi. E like me ke kaha ?ele?ele i ke ki?i e hō?ike nei, waiho ?ia nā mea hao a puni nā kihi e hana hou ?ia e like me he koena.

?

?O ka helu o ka extrusion hilina?i ?ia i ke oka a kaomi ?ia a me ke ?ano o ka puka puka make. ?O ka ho?ohana ?ana i nā mea pa?a pa?a e ?omi i nā mea hana ma?alahi hiki ke lohi e like me 1-2 kapua?i i kēlā me kēia minuke. Me nā mea palahalaha, hiki ke kaomi ?ia i nā ?ano ma?alahi i 180 kapua?i i kēlā me kēia minuke a ?oi.

?O ka lō?ihi o ka huahana extrusion pili i ka ?aukā alumini a me ka puka puka puna. Hiki i kahi extrusion ho?omau ke hana i kahi huahana a 200 mau kapua?i ka lō?ihi. ?O ka extrusion extrusion hou loa, ke ha?alele ka huahana extruded ua kau ?ia ka extruder ma ka pahe?e (e like me ke kā?ei lawe);

Wahi a ke kinikini ?oko?a, ka extrusion mai ka mode hō?olu?olu huahana: ho?oka?awale ?ia i loko o ka ho?olu?u kūlohelohe, ka ea a me ka wai anuanu akā ke kinai. He kī nui kēia e hō?oia i ka hana metalagraphic o ka huahana ma hope o ka ?elemakule. Lawe ?ia ka huahana extruded i he moena anu.

Pololei

Ma hope o ke kinai ?ana (ho?onuanu), ho?opololei a ho?opololei ?ia ka huahana extruded e kahi kauā a i ?ole straightener (ua kaulike ?ia ho?i ke kau ?ana me he hana anuanu lā ma hope o ka extrusion). I ka hope loa, ua lawe ?ia ka huahana i ka mīkini sawing e ka mea lawe lawe.

Pepeiao

?O ka hana ?ana o ka hana ma?amau ma?amau ka pahi olo o kahi huahana i kahi lō?ihi pā?oihana kiko?ī. ?O nā pahi olo pō?ai ka mea e ho?ohana ākea ?ia i kēia lā, e like me nā pahi lima ho?oka?a e ?oki?oki i nā ?āpana lō?ihi o nā mea extruded vertic.

Aia kekahi mau ?oki i ?oki ?ia mai ka piko o ka ?ikepili (e like me ka pahi olo uila). ?O ka pākaukau ?ike pono pū kekahi, ?o ka papa ?aina me kahi pahi ?ike disc mai lalo a luna e ?oki i ka huahana, a laila ho?i ka pahi kani i lalo. o ka pākaukau no ka pō?aiapuni a?e.

?O 16 saw iniha ke ana pō?ai puni i anawaena a ?oi aku ma mua o 100 mau niho karbide. Ho?ohana ?ia nā pahi nunui no nā extruders diameter nui.

Ho?okomo ?ia ka mīkini wili hana ho?oli?ili?i pono?ī me kahi ?ōnaehana e hā?awi i ka lubricant i ka lā?au kani e hō?oia i ka maika?i o ka hana kani ?ana a me ka ?ili o ka pahi olo.

Mālama kahi kaomi kaomi i nā ?āpana i kahi no ka pahi ?ana a ?ohi?ohi ?ia nā ?ōpala ?ili no ka hana hou ?ana.

?Elemakule:

Pono kekahi mau huahana extruded i ka ?elemakule e loa?a ai ka ikaika optimum, no laila ua kapa ?ia ia he ?elemakule. Hana ?ia ka ?elemakule kūlohelohe i ka mahana o ka lumi. Lawe ?ia ka ?elemakule artipisyal i loko o ka umu ?elemakule.

Ke kāpae ?ia ka ?ikepili mai ka extruder, lilo ka pili i semi-solid. Akā pa?a koke ia ke anuanu a kinai ?ia paha (?o ke anuanu a ?olu?olu paha ka wai.

Ho?oikaika ?ia nā alloy alumini mālama ?ole ?ia (e like me nā ?anela aluminika me ka magnesium a me ka manganese i ho?ohui ?ia e ka ?elemakule kūlohelohe a me ke anuanu e hana ana. e ka ho?opili ?ana i ka mālama ?ana i ka wela o ka hana metallographic oka a.

Eia kekahi, ?o ka ?elemakule e hana i nā ?āpana o ka pae i ho?oikaika ?ia i ho?oka?awale kaulike ?ia e loa?a ai ka nui o ka ikaika o ka hua, ka pa?akikī a me ka pa?a o ke kinikini kūikawā.

Balesa

Inā ?ohana ?elemakule a i ?ole ?elemakule o ka mahana o ka lumi, ma hope o ka piha ?ana o ka ?elemakule, ua ho?ohuli ?ia ka ?ike i ka papa hana ma?a a i ?ole ka papa hana hohonu a i ?ole nā ??bales i mākaukau no ka lawe ?ana i ka mea kū?ai.

Nīnau pū ka po?e

Ka manawa Post: Mar-20-2020