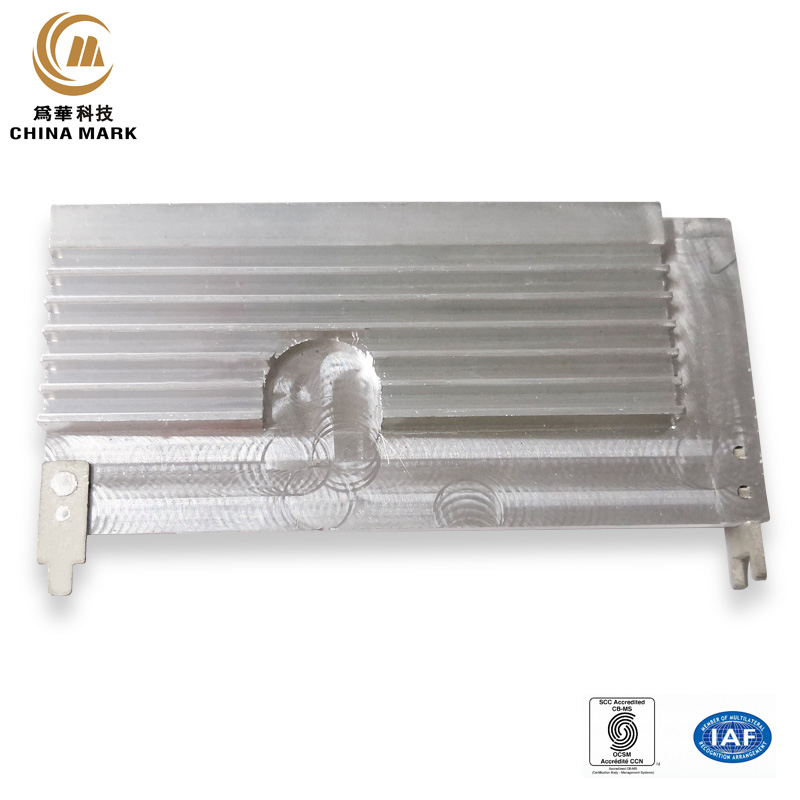

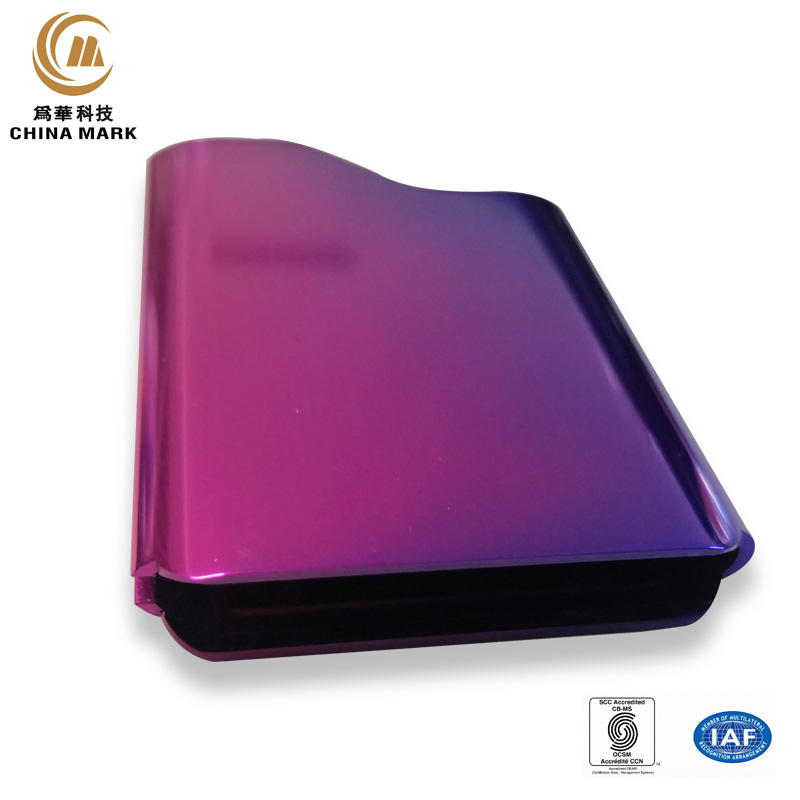

?O ka extrusion alumini: ?O ke kinikini alumini (deformation) ingot extrusion molding process me ka extruder.

?Oihana ?enehana extrusion alloy

Ho?oka?ina o nā ?ao?ao extruded:

Paukū pa?a: ?a?ohe puka o ka ?āpana.

Hollow profile: he mau puka ko ka ?ao?ao pili.

'Ole a me ka ho?olālā o ka ma?alahi extrusion make:

?O ka Tube extrusion extrusion e make aia ?elua: ?o ka mea mua kahi extrusion make make. ?O ka lua o ka hollow profile extrusion die. ?O ke ?ano kiko?ī penei:

1) pahu pahu extrusion: kahi kino paukū multi-layer i hana ?ia i ke kila kila ki?eki?e, hiki ke ho?oku?u ?ia me ka pale o loko. Ho?oholo ?ia ka lō?ihi e like me ka ton extrager. Mea Pono: coat 5CrMnMo, 3Cr2W8V i ho?onohonoho ?ia.

2) kāko?o punahelu: hō?oia i ka punahelu a me ka popopo pad i concentric, mea e ho?ouka i ka punahelu, punahelu pad kāko?o mea hana.

3) pad pad: ua like ka nui o ka pad die a me ka die, ?o kona mānoanoa he 3 mau manawa o ka mānoanoa make, a halihali pū me ka die extrusion me ka make. Die pad, make ka nui o ka puka make ma mua o ka punahelu. : mea kila oka hao.

4) kaomi kaomi: nā mea kōkua kōkua e hō?oia i ka ne?e ?ole o ka mo?o i ka wā extrusion a pili pono me ka pahu extrusion. Ho?oholo ?ia ke ?ano a me ka nui e like me ka tonnage o ka extruder.

5) extrusion gasket: mea kōkua kōkua e pale aku i ka ho?opili pololei ?ana ma waena o ka lā?au extrusion a me ka metala extruded. ?Oi aku ka li?ili?i o ke anawaena o waho i ke anawaena o ka pahu extrusion, a ?o kona mānoanoa aia ma waena o 40 mm a me 150mm.

6) lā?au extrusion: ke hana ka lā?au extrusion, komo ia i loko o ka cylinder extrusion a me nā pilina me ka pad extrusion. Ho?okomo ?ia ka mea lawe extrusion i ka kaomi extrusion ki?eki?e o ka extruder. Mea Pono: 3Cr2W8V.

?O ke kumu ho?onohonoho hole make:

?O ka ho?onohonoho ?ana o ka lua kūmole hole: ?o ka mea ma?amau ka kikowaena o ka umekaumaha a me ke kikowaena mould i kūlike. Inā ?oko?a ka mānoanoa o ka paia, pono e ho?onohonoho ?ia ka hapa lahilahi i waenakonu o ka puna.

?O ka ho?onohonoho puka make porous profile: no ka ?āpana li?ili?i a i ?ole ?āpana symmetry maika?i ?ole, ho?ohana pinepine ?ia i ka popo porous. ?A?ole pono ka li?ili?i ma waena o nā lua o ka popo popo.

Ka ho?oholo ?ana i ke kā?ei hana puka make:

1) e lawe i ka ?āpana āpau e like me ka pae ho?ohālikelike, kahi o ka lō?ihi e hana ai (1.5 a 2) mau manawa o ka mānoanoa o ka huahana i ho?opau ?ia.

2) ?o ka lō?ihi o ka pae hana e pili ana i kahi kiko kuhikuhi ka lō?ihi o ka bande hana ma ka helu kuhikuhi me 1mm.

3) me ka mānoanoa like, ?o ka lō?ihi o ka hana ma ka mamao like mai ke kikowaena o ka hopena he like.

4) e ho?omaka ana mai ke kikowaena o ka mould, hiki ke hā?awi ?ia i ka ho?onui a me ka hō?emi ?ana o ka lō?ihi hana o kēlā me kēia mamao o 10mm i nā puke pili pono.

5) nā pahi hakahaka i ke kā?ei hana: ?o nā pahi hakahaka loa e ho?onāwaliwali i ka ikaika o ke kā?ei hana o ka popopo.

Poloka huina:

Ke ?oi aku ka lō?ihi o ka hana o ka puka make ma mua o 15 a 25mm, i ka ?oia?i?o, ?a?ole kūpono ke metala me ke kaha hana ma muli o ka nui o ka shrinkage, i kēia manawa, hiki ke ho?oponopono i ke ana kahe o ka mea hao e ka Angle ālai. ?O ka Angle ma waena o ka busbar a me ka laina kikowaena extrusion o ke kā?ei hana ka ālai ?ana i ka Angle, a ?o ka mea ?oi loa ka poloka ?o Angle he 3 a 5 kekelē.

?O ka huina kahe: ?o ka mea nui, ?o ka kahe kahe kahi sime symmetrical cone a i ?ole he kone hū ?ia ma ka helehelena hopena o ka punahelu.

?O ka mea i luna e pili ana i ka mea extrusion alumini a me ka ?enehana extrusion alumini e pili ana i ka ho?olauna ?ana: He ?oihana mākou ka hana extrusion alumini ?oihana, hiki ke hā?awi: arc aluminika extrusion, triangle alumini extrusion a me nā lawelawe lawelawe hana pilikino pilikino ?ia. Welina e kūkākūkā ~

Ka manawa o ka manawa: Apr-11-2020