Af? 20 nke ah?mah? na oyi na-at? / ?b?aru / ?l? ?r? na-ekpo ?k? nke aluminom alloy, na-elekwas? anya na-emeghe oghere na punching / ?b?aru / ibe ya / CNC mmep?ta na nhazi nke ngwaah?a aluminom, aluminum extrusion ebu.

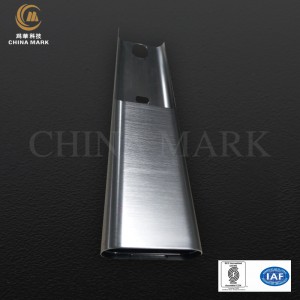

Aluminom extrusion maka China sayens? na tekn?z?, nke a na-ejikar?, edemede zuru ezu, mma magburu onwe ya, ?r? mb?, mmet?ta extrusion aluminom nwere ike ahaziri d? ka mkpa d? iche iche, nabata ?kp?t?r?;

?Aluminom extrusion uminumgha extrusion usoro

?I. usoro ?r?:

1. Kpoo ingind cylinder ka 380 ℃ - 420 ℃ n'?d? gradient kpo oku nke 100 ℃ / 1 awa.

2. D? ka mpempe akw?kw? at?mat? ?r?, h?r? ego kwes?r? ekwes? nke ?k? ?k? ?k? ?k? kwes?r? ekwes? na 480 ℃ - 520 ℃, profa?l? mmep?ta ihe p?r? iche d?ka usoro usoro ak?wap?tara.

3. D?ka at?mat? ?r? ah?, h?r? ebu d?ka at?mat? ah? si d?, kpoo ya ?k? ruo 460 ℃ - 500 ℃, ma mee ka ? d? ?k? ruo awa 2-- 4.

4. Malite igwe na-eme ka igwe j?r? oyi - moto mman?.

5. D?ka otu usoro nke at?mat? ah? si d?, h?r? ah?h?a p?r? iche maka ebu a ga-etinye ya na nt?ala ebu ah?, wee kp?chie nt?ala ebu ah? na ?n?d? extrusion.

6. Mkp?chi jidere drum na ebuli kp? ?k? n'?n? aluminum mmanya na kwek?? ?n?d? nke ihe gallbladder site na iji nri ogbe.

7. Master cylinder na-at? extrusion

8. Mbido ?p? mb? kwes?r? ?d? nway? nway?, ma a ga-edozi usoro ?kara dabere na ogo nke profa?l? na np?p?ta ah?.

9. Dek?? ?n??g? ebu, n?mba ogwe aluminom, nr?gide cylinder isi na ?gbanye ?s? na nk?wa zuru ezu na ndek? mb?.

?Ndi. Usoro ch?r?

1. ?n?d? okpom?k? nke aluminom mkpanaka kpo oku na igwe b?: A ewep?gh? anw?: 500 ℃ - 520 ℃ b. gbawara n'etiti: 480 ℃ - 500 ℃ c. a na-egbu ihe eji emep?ta ?l? ?r? p?r? iche d?ka usoro ch?r? p?r? iche.

2. Ebu kpo oku usoro: a. ewep?gh? anw?: 460 ℃ - 480 ℃ b. nkewa kewara: 460 ℃ - 500 ℃

3. Nt?ala tube d? ?k?: 380 ℃ - 420 ℃ njedebe ihu elu nke ingot tube b? 280 ℃ - 360 ℃

4. Ihe a na-emeghar? anya ga-enwer?r? ihu ?ma, enwegh? mmet?ta aka maka ogologo oge, ezi na ?b?nad? ?ka na-ap? ap?, enwegh? eriri na-enwu gbaa, akara ojii, oghere ?gb?elu n'etiti ?gb? elu Yin na Yang, nt?ghar? ihu, na ak?k? mbep? kwes?r? ?d? elu nkenke lar?? d? ka ?k?l?t? mba.

5. Ntughari mgbat?: ≤200㎏ / cm2

6 mgbali mkp?chi gall 120㎏ / cm2 - 150㎏ / cm2.

7. Okpom?k? nke mman? hydraulic ≤45 ℃

8. A na-ach?kwa ?s? ?s? profa?l? na: 5 m / min --30 m / min

10. ? b?la extrusion nke 80 mkpara -100 mkpara, ga-eji p?r? iche ?cha cylinder kwachaa hichaa bile.

?At?. Okwu ch?r? nlebara anya

1. N'oge extrusion, ? b?r? na a na-ak?nye ?nw?, oge mmebi agagh? agafe 5 sek?nd.

2. Mgbe ? na-etinye ebu ah?, ,aa nt? na nchekwa ma gbochie nkedo ah? ?p? na ?k?tu ?kw?.

3. Mgbe ?ghas?r?, amachibidoro ?banye pip? kp?mkwem n'ime ntaneti.

4. Tupu irite ?nwu ah?, a ga-enyochar?r? ?n?d? etiti ya na mgbakwunye extrusion. Igwe nyocha a na-enwegh? ibu ga-agba ?s? otu ugboro tupu ?malite igwe.

5. Ma ??t??t?? okpom?k? nke okporo osisi ??t??t??, ebu na ingot gb?mgb?m na-ezute ihe nd? a ch?r?.

6.3 - lelee ogo 5 mkpara otu oge.

Lelee mman? ?k? ugboro ugboro.

8. Ma mmanya aluminom ? b?la nwere akara akara ?k? na akara ngosi.

?

?