Aluminom extrusion usoro

Usoro ihe eji emeputa ihe nke aluminom na amalite site na imeputa ihe, n'ihi na ihe eji emeputa ihe a bu ihe eji achoputa ya, nke na achoputa otutu ihe ndi ozo. , Njirimara nd? a na ihe nd? ach?r? n'ezie na-ekpebi nh?r? nke extruded aluminum alloy.

Agbanyegh?, ak?r?ngwa nke aluminom na-emep?tagh? ekpebi site na ?d? okike nke ngwaah?a a.?d?d? ngwaah?a a na-ekpebi ?d?d? nke extrusion anw?.

Ozugbo edozi nsogbu ah?, usoro extrusion ah? bara uru na-amalite nkedo extrusion na mkpanaka aluminom, a ga-ewep? mkpanaka nkedo nke aluminom tupu extrusion mee ka ? d? nro, a na-etinye ihe ?k?k? d? mma nke aluminom na-etinye na ingng na-etinye n'ime gb?mgb?m n'ime, wee jiri elu ike ha?dr?lik na-ebughar? mkpanaka extrusion, njedebe njedebe nke mkpanaka extrusion nwere ihe nr?gide, ihe d? otú ah? d? nro nke aluminom na ng?ng? na-enwe nr?gide siri ike site na nkenke nkenke na-akp?zi extrusion.

Nke a b? ihe ebu maka: ?d?d? nke ngwaah?a ach?r? maka imep?ta.

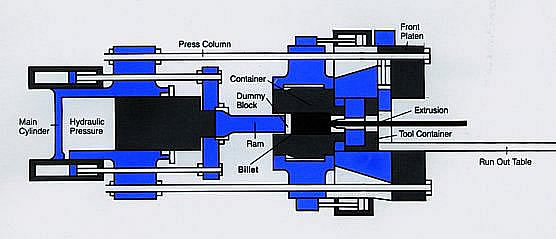

The ndise b?: ah?kar? kehoraizin ha?dr?lik extruder schematic esereese

Uzo nke extrusion bu aka ekpe rue aka nri

Nke a b? nk?wa d? mfe nke extrusion a na-ejikar? eme ihe taa. Mgbat? na-enwegh? isi b? usoro yiri ya, mana enwere ?f?d? esemokwu d? oke mkpa.

Na usoro ntughar? na-ap? ap?, a na-etinye ihe nwuru anw? na oghere extrusion, nke mere na a na-agbanye anw? ah? na-enwegh? oghere aluminom, na-amanye alloy alloy ka ? gbasaa n'ak?k? oghere extrusion site na ?nw?.

N'ezie, usoro extrusion d? ka ?p?k?ta ezé ezé. Mgbe a na-etinye nr?gide na ngw?s? ngw?cha nke ezé ezé, a na-ap?s? ezé na-eme ka eze na-egbuke egbuke site na oghere okirikiri.

? b?r? na oghere ya d? lar??, eze p?r? ap? na-ap?ta d? ka r?b?n.

N'ezie, enwere ike ?p?p?ta ?d? ihe mgbagwoju anya na oghere nke otu ?d? ah?. D?ka ?m?maat?, nd? na-eme achicha na-eji tubes d? iche iche ap?p?ta ice cream iji mee ?d? ?d? frill niile.

? b? ezie na ?nwegh? ike iji ngwaah?a ma ? b? ice cream mee ?t?t? ngwaah?a bara uru, ? gagh? enwe ike iji mkp?s? aka g? tinye aluminom n'ime akpa.

Mana ? nwere ike iji igwe hydraulic d? ike wep?ta aluminum site na ?d? nke ebu iji mep?ta ?d? ngwaah?a d? iche iche bara uru nke ? f?r? nke nta ka ? b?r? ?d? ? b?la.

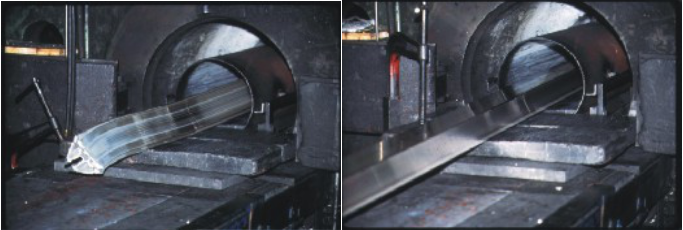

Ihe osise d? n'okpuru (n'aka ekpe) na-egosi ak?k? mb? nke onye na-ebido ihe na mbido extrusion. (n'aka nri)

Ogwe

Ogwe aluminom b? oghere nke usoro extrusion. Ogwe aluminom eji mee ihe maka extrusion nwere ike sie ike ma ? b? oghere, na-ab?kar? cylindrical, a na-ekpebikwa ogologo ya site na tube extrusion.

A na-ejikar? ogwe osisi aluminom eme ihe site na nkedo, ma ? b? site na ibe ma ? b? nt? nt? .? na-emekar? site n'?h? osisi aluminom alloy na ngwongwo d? mma.

A na-ejikar? ihe nd? e ji ígwè r?? mee ihe d? iche iche nke aluminom. Extrused Aluminom alloys mejup?tara Ch?p?ta (na-ad?gh? ihe kar?r? 5%) ?cha (d? ka ?la k?pa, magnesium, s?l?k?n, manganese, ma ? b? zinc) na-eme ka ihe onwunwe nke ezigbo aluminom d?kwuo mma ma na-emet?ta usoro extrusion.

Ogologo nke aluminom di iche site na onye na-emeputa ihe na onye na-emeputa ihe, nke kpebisiri ike site na njedebe ikpeazu ach?r?, ntinye extrusion, nkw?s? nzipu na nnyefe extrusion.

Ogologo ?k?l?t? n'ozuzu ha sitere na 26 sentimita asat? (660mm) ruo 72 sentimita asat? (1830mm). Ak?k? nd? d? n'èzí sitere na 3 sentimita asat? (76mm) na 33 sentimita asat? (838mm), 6 sentimita asat? (155 mm) na 9 sentimita asat? (228 mm).

Direct usoro ntanye

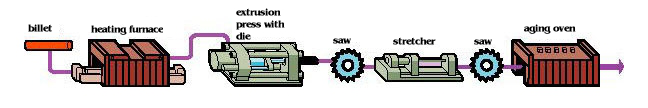

[billet] [ikpo ?k? na-ere ?k?] [extrusion press with die] h?r? [strecher] [na-eme agadi n'abal?]

Ihe osise ah? na-egosip?ta usoro nd? b? isi nke ?gbanye ogwe aluminom

?

Mgbe akara ngwaah?a ikpeaz?, ah?r? alloy kwes?r? ekwes?, ar?p?ta ihe ?k?k? extrusion gw?chara, na nkwadebe maka usoro mgbat? ah? n'ezie.

Mgbe ah? kpoo mmanya aluminom na ngwá ?r? extrusion. N'oge usoro extrusion, ogwe aluminom siri ike, mana ? d? nro na ?k? ah?.

Ebe mgbaze nke alloy alloy b? ihe d?ka 660 The. ?n?d? okpom?k? nke kpo oku nke usoro extrusion d?kar?s?r? kar?a 375 ℃ ma nwee ike ?d? elu kar?a 500 ℃, dabere na ?n?d? extrusion nke metal.

Usoro nbido ah? n'ezie na-amalite mgbe mkp?s? osisi na-amalite itinye nr?gide na mkpanaka aluminom na ntinye.

Ezubere hydraulic d? iche iche ?p?k?ta ihe ? b?la site na 100 t?n ruo t?n 15,000. Nr?gide a nke extrusion na-ekpebi oke nke extrusion nke igwe extrusion mep?tara.

A na-egosi nk?wap?tap?tap?tap?tara nke kachas? oke ak?k? nke ngwaah?a a, oge ?f?d?kwa site na ngwaah?a ah? d? gburugburu.

Mgbe extrusion ah? ka malitere, a na-etinye ogwe aluminom na ike nke mmeghachi omume nke ebu ma na-ad? mkp?mkp? ma sie ike, ruo mgbe a ga-agbasawanye ogwe osisi aluminom site na mgbidi ingot barrel;

Mgbe ah?, ka nr?gide ah? na-ar?wanye elu, ígwè nro (nke siri ike) enwegh? ebe ? ga-aga ma malite ?p?p?ta ya site na oghere nke ebu ah? na ns?t? ?z? nke ebu ah?, na -emep?ta profa?l?.

Ihe f?r? nke nta ka ? b?r? 10% nke mkpanaka aluminom (g?nyere akp?kp? ah? nke aluminom) ka a hap?r? na gb?mgb?m ingot, a na-ebip? ngwaah?a extrusion site na ebu ah?, ma kpochaa ?la nke f?d?r? n'ime gb?mgb?m ingot ma meghar?a ya. usoro sochirin? b? na a na-any?p? ngwaah?a extrusion d? ?k?, mezie ya ma mee agadi.

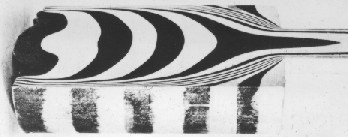

Mgbe aluminom kpoputara site na ebu site na ingot cylinder, ihe di n'etiti etiti aluminom na-agbanye ngwa ngwa karia onu. Dika nwa ojii na ihe osise a na-egosi, a na-ahazi metal di gburugburu ka emegharia ya dika ihe f?duru.

?

?n?ego nke extrusion na-adabere na alloy na-afanyekwa na ?d?d? nke oghere ntanet? anw?. N'iji ihe eji eme ihe iji kpoo ihe ndi ozo di egwu dika 1-2 dika nkeji. Site na alloy di nro, enwere ike ichota ihe di mfe na 180 nkeji kwa nkeji ma obu karie.

Ogologo nke ngwaah?a extrusion na-adabere na ngwongwo aluminom na oghere ntanye ebu. Extrusion na-aga n'ihu nwere ike mep?ta ngwaah?a ruo 200 ?kw? ogologo.Nke a na - akp?zi ihe kachas? ?h?r?, mgbe ngwaah?a a na - ap? ap? ga - etinye ya na slide (ya na eriri ebu ebu);

D? ka alloy d? iche iche si kwuo, a na-at?ghar? extrusion site na ?n?d? j?r? oyi nke ngwaah?a: kewara n'ime obi j?r? oyi, ikuku ma ? b? mmiri j?r? ma quenching.This b? isi ihe d? mkpa iji h? na ar?m?r? nke metallographic nke ngwaah?a ah? mgbe ?ka nká. akwa oyi.

Kw?zie

Mgbe emechara (j?r?), a na-agbat? ngwaah?a ah? ma ? b? dozie ya site na onye na-ebughar? ma ? b? na-agbat? (agbat? na-ar? ?r? d? ka oyi na-ar? ?r? mgbe extrusion gas?r?) .N'ikpeaz?, a na-ebufe ngwaah?a ah? na igwe ?wa ah? site na ngwa?r? ah?.

?k? mmiri

Pd? ?kp?chas? ngwaah?a a na-ah?kar? b? ?wa ah? nke ngwaah?a na ogologo az?mah?a.? b? s?s? okirikiri ka a na-ejikar? eme ihe taa, d? ka ngbanye aka nke na-agaghar? agaghar? nke na-egbutu ogologo nke ihe nd? a na-ap? ap?.

E nwekwara nkw? iberibe si n'elu profa?l? (d? ka eletriki miter h?r?) .? bara uru h?r? teb?l, h?r? table b? na a diski h?r? ag?ba na ala na-ebip? ngwaah?a, na mgbe ah? na nkw? ihu nloghachi az? na ala nke okpokoro maka okirikiri ?z?.

A ah?kar? okok?re okirikiri ikwo b? 16-20 sentimita asat? na dayameta na nwere ihe kar?r? 100 carbide ezé. A na-eji ah?h?a buru ibu maka nd? na-ebubata nnukwu dayameta.

A na-eji igwe na-ete mman? na-ar? ?r? nke nwere sistem? na-enye mman? n'?k? iji h? na ar?m?r? kachas? mma na ar?m?r? nke elu.

Igwe na-akpagh? aka na-ejide ak?k? nd? ah? maka ?kwa ahihia ma kpok?ta mkpofu irighiri ihe maka imeghar? ihe.

Agka:

F?d? ngwaah?a nd? a na-emep?ta na-ach? ?ka nká iji nweta ike kachas? mma, ya mere a na-akp?kwa ya ?ka nká.Nke a na-eme agadi na-ekpo ?k? na-ekpo ?k? na-ekpo ?k? na-ekpo ?k? na-ekpo ?k?.

Mgbe profa?l? si na onye na-ekpochapu ?k?, profa?l? na-agh? nke siri ike.Ma n'oge na-ad?gh? anya ? ga-esi ike mgbe ? j?r? ma ? b? kp?nw? (ma ? b? ikuku ikuku ma ? b? mmiri oyi).

Nd? na-anagh? ekpo ?k? na-ekpo ?k? alloys (d? ka alloys alloys na mgbakwunye magnesium ma ? b? manganese) na-ewusi ike site na ?ka nká na oyi na-ar? ?r?. Heat ?gw?gw? aluminom alloy (d? ka alloy alloy na ?la k?pa, zinc, magnesium + silicon) nwere ike inweta ezigbo ike na ike site na-emet?ta ?gw?gw? ?k? nke alloy metallographic structure.

T?kwas? na nke ah?, ?ka nká b? ime ka ak?k? nke usoro ah? siri ike na-ekewap? iche iji nweta oke mkp?r?, ike na ekwedo nke alloy p?r? iche.

Bales

Ma nk? ?k? ?k? ma ? b? ime ?l? ?ka nká, mgbe ?ka nká zuru oke, a na-ebufe profa?l? na ?gw?gw? elu ma ? b? ogbako nhazi miri emi ma ? b? mgbat? d? njikere maka ibuga nd? ah?a ah?.

Nd? mmad? na-aj?kwa

Post oge: Mar-20-2020