Polishing na-ezo aka iji polishing wax, hemp wheel, nylon wheel, akwa wheel, wind wheel, waya ákwà wiil na nd? ?z? polishing ngwa?r? na abrasive ah? ma ? b? nd? ?z? polishing media iji gbanwee elu nke workpiece iji belata n'elu roughness nke workpiece. iji nweta na-egbuke egbuke , Usoro nhazi ihe eji ach? mma maka elu d? lar??.Usoro a nwere ike imeziwanye nguzogide corrosion na mmet?ta na-egbuke egbuke nke igwe anagh? agba nchara.

Yab?, kedu ?z? a na-ejikar? igwe anagh? agba nchara polishing maka any??l? ?r? ahanand? na-emep?ta aha aha igwe?

Nke a b? ?z? polishing any? na-ah?kar?:

1 Mechanical polishing:

N'iji tekn?z? a, enwere ike nweta oke ike nke Ra0.008μm, nke kachas? elu n'etiti ?z? polishing d? iche iche.

2 Chemical polishing:

Isi uru nke usoro a b? na ? d?gh? ach? ngwá ?r? d? mgbagwoju anya, nwere ike ime ka ihe nd? na-ar? ?r? na-eme ka ? d? mgbagwoju anya na-egbuke egbuke, ma nwee ike ?meghar? ?t?t? workpieces n'otu oge, na-ar? ?r? d? elu.?kp?kp? elu enwetara na-ab?kar? ?t?t? μm 10, nke a na-ejikar? eme ihe n'ime ?d? polishing asaa.

3 Electrolytic polishing:

? nwere ike iwep? mmet?ta nke mmeghachi omume cathodic, na mmet?ta d? mma.N'otu oge ah?, ? nwere ike ?bawanye nguzogide corrosion nke igwe anagh? agba nchara, melite izi ezi nke ngwá ?r? d? iche iche d? iche iche, ma mee ka ihe nd? d? mkpa na ígwè d? mkpa kwa ?b?ch? d? mma na ihe nd? ?z?. ? dabara maka ígwè, aluminum, ?la k?pa, nickel na ngwaah?a nd? ?z?.Alloy polishing.

4 Ultrasonic polishing:

The macroscopic ike nke ultrasonic nhazi b? obere, na ? gagh? eme ka deformation nke workpiece.

5 Nchacha mmiri mmiri:

abrasive jet machining, mmiri mmiri jet machining, hydrodynamic egweri, wdg.

6. Magnetik egweri na polishing:

Usoro a nwere nhazi nhazi d? elu, ?d? mma d? mma, njikwa d? mfe nke ?n?d? nhazi na ?n?d? ?r? d? mma.?d?iche d? n'elu nwere ike iru 0.1μm.

7. Chemical n'ibu polishing:

nwere ike nweta oke ala site na nanometer ruo ?kwa at?m.?z?kwa, mmet?ta enyo na-egbuke egbuke nwere nnukwu nchap?ta, enwegh? mmej?, yana ezigbo flatness.

D? ka ya d? iche iche polishing akara ule, ? nwere ike kewara n'ime nd? na-eson? akara ule nke igwe anagh? agba nchara polishing ?kp?k?:

1. ?kwa ihie

E kewara ihe nch?p?ta nchap?ta n'ozuzu n'ime 2K, 5K, 8K, 10K, 12 mmet?ta elu.?ganihu d? elu, mmet?ta d? elu ka mma na ?n?ah?a d? elu.

D? ka usoro nlele anya si d?, a na-ekewa nchap?ta nke elu igwe anagh? agba nchara nchara n'ime akara 5:

?kwa 1: Enwere ihe nkiri oxide na-acha ?cha n'elu, enwegh? nchap?ta;

?kwa 2: Na-egbukep? ntak?r?, enwegh? ike ?h? ndep?ta ah? nke ?ma;

?kwa 3: ìhè ka mma, a p?r? ?h? nk?wap?ta;

?kwa 4: Elu na-egbuke egbuke, a p?kwara ?h? ihe ndep?ta ah? n'?z? doro anya (dak?tara na elu elu nke electrochemical polishing);

?kwa 5: Nchap?ta d?ka enyo.

A na-ejikwa igwe anagh? agba nchara n'?t?t? ebe n'ihi nnukwu nguzogide corrosion na ihe ?ch? mma, kar?s?a na ngwa ah?ike, ngwa ?l? ?r? nri, tableware, ngwa kichin, wdg. ? na-ewu ewu ma kwalite.

? b?r? na ? nwere mmas? na nd? a ma ch?? ?matakwu banyere yaka esi ehichaa efere aha, otu esi ehicha n?mba ?l? ?la, Kedu ka esi enwu efere aha igwenaKedu ka esi ehicha ?la a kanyere akara, biko lelee any? ukara website ?m?takwu, ma ? b? kp?t?r? any? ah?a nd? ?r? ozugbo.

M?takwuo maka ngwaah?a WEIHUA

Any? b?ara ebe a ijere g? ozi!

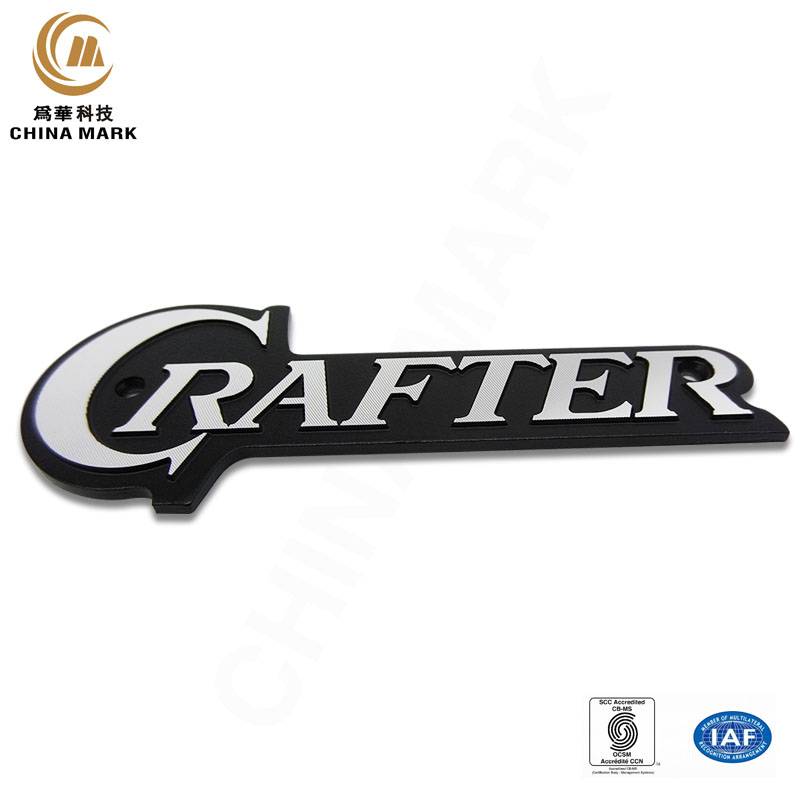

Efere akara ngosi ?la omenala- any? nwere ah?mah? na nd? omenkà z?r? az? nd? nwere ike ?mep?ta ihe a p?r? ?dabere na ya, ngwaah?a njirimara metal d? elu na-eji ?d? ihe ? b?la emecha na ihe eji eme ihe n'ah?a taa. Any? nwekwara nd? na-ere ah?a maara ihe ma na-enyere aka na-echere ?za aj?j? ? b?la ? nwere. Any? n? ebe a. iji nyere g? aka ime nh?r? kacha mma maka g?igwe aha!

Oge nzipu: Eprel-07-2022