Metal extrusions,Radar fitting-upright post | WEIHUA

What is metal extrusion processing?

Metal extrusions processing is an important method of pressure processing using the principle of metal plastic forming. Metal ingots are processed into tubes, rods, T-shaped, L-shaped and other profiles at one time through extrusion.

Metal extrusion press is the most important equipment to realize metal extrusion processing Extrusion is one of the main methods for the production of non-ferrous metals and stainless steel materials and the forming and processing of parts.

It is also an important method for the preparation and processing of advanced materials such as various composite materials and powder materials.

From the hot extrusion of large-size metal ingots, the hot extrusion of large pipe and rod profiles to the cold extrusion of small precision parts, the direct solidification and molding of composite materials from powder and pellets to intermetallic compounds, For difficult-to-process materials such as superconducting materials, modern extrusion technology is widely used.

Classification of extruded aluminum

According to the metal plastic flow direction, extrusion can be divided into the following categories:

Positive extrusion:

During production, the direction of metal flow is the same as that of the punch

Back extrusion:

During production, the direction of metal flow is opposite to that of the punch

Compound extrusion:

During production, the flow direction of a part of the blank is the same as that of the punch, and the other part of the metal flows in the opposite direction of the punch.

Radial extrusion:

During production, the direction of metal flow is 90 degrees to the direction of movement of the punch.

Features of extrusion processing

Extrusion processing is characterized by a strong three-dimensional compressive stress state, which is beneficial to improve the plastic deformation ability of the metal, improve the quality of the product, and improve the internal microstructure and performance of the product.

In addition, extrusion processing also has the characteristics of wide application range, high production flexibility, simple process flow and low equipment investment.

The most widely used materials for extrusion processing are low-melting non-ferrous alloys, such as aluminum and aluminum alloys.

Cold extrusion VS Hot extrusion

One, different process

Cold extrusion: In the process of cold extrusion, the metal blank is extruded without heating.

Hot extrusion: In the process of hot extrusion, the metal blank is heated to the hot forging forming temperature for extrusion.

Second, different equipment

Cold extrusion: The equipment used for cold extrusion includes mechanical presses, hydraulic presses, etc.

Hot extrusion: The equipment used for hot extrusion includes induction heating equipment and hot extrusion dies.

Three, different applications

Cold extrusion: Cold extrusion is mainly used in the refined production of small and medium forgings.

Hot extrusion: Hot extrusion is mainly used in the manufacture of long parts and profiles with common cross-sections.

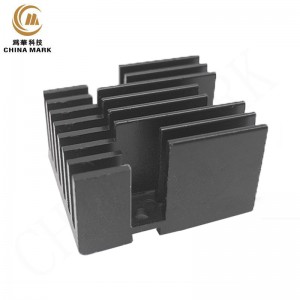

If you need to find a professional, affordable, long-term and stable aluminum extrusion supplier, contact us to make your cutom metal extrusion product.

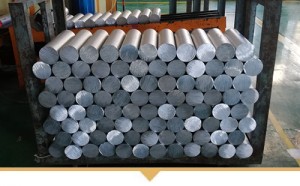

The main process shows as below

Step 1:6063 round bar ?100*350MM

Step 2:Natural gas environmental protection aluminum rod heating furnace

Step 3:Electromagnetic mold heating furnace

Step 4:1000 tons of high-precision profile extruder

Step 5:Natural gas environmental protection aluminum aging furnace