Metal name plate maker,High-end aluminum nameplate | WEIHUA

Weihua Technology, the reason why the company is named Weihua, as the name implies, is for China, in order to build a reputation for China's hardware signs and form a unique China mark manufacturer.

Types of custom metal nameplates we can do:

Computer nameplates, monitor signs, audio signs, amplifier signs, air conditioning signs, various furniture signs, various kitchenware signs

Machinery industry signs, various medical equipment signs, etc.

Material: aluminum, aluminum alloy, stainless steel, nickel, copper, iron, etc.

How to make:

Stamping aluminum nameplates, forging signs, silk-screen signs, brushing signs, anodized signs, stainless steel etching signs, electroforming signs, engraving signs, CD pattern signs, electroplating signs, etc., and can also punch holes, paste adhesives, and install screws.

Manufacturing equipment for various signs:

Continuous high-precision punching machine, precision pneumatic punching machine, hydraulic press, automatic printing machine, anode line, automatic spraying line, automatic cleaning line, double-head engraving machine, ordinary laser engraving machine, four-axis laser engraving machine, three-dimensional dispenser, batch Flower machine, marking machine, plane polishing machine, CCD full inspection machine, etc.

Available inspection equipment :

2.5-dimensional image measuring instrument, standard light source machine, program constant temperature and humidity test machine, electric heating and constant temperature water bath, low temperature freezer, high temperature test machine, tape retention test machine, friction resistance test machine, pointer push-pull meter, electric push-pull force Testing machine, folding durability testing machine, RCA paper tape abrasion tester, universal material testing machine, Shore hardness tester, lifting test machine, digital multimeter, salt spray testing machine, digital coating thickness gauge (film thickness gauge) , digital display level, sealing tester, sealing tester, resistance tester, computerized tensile tester, pencil hardness tester, vibration and abrasion tester, normal temperature yellowing resistance tester, moisture-proof machine, drop hammer tester, Furnace temperature tester, gloss meter, UV energy meter, electrostatic tester, illuminance meter, dust particle counter, color difference meter, two-dimensional code scanner, automatic bending test machine, ultraviolet aging test machine, thermal shock test machine , Withstand voltage tester, PH meter, 100 grid knife, angle gauge, metallographic microscope, Newton pen, digital micrometer, etc.

Aluminum (.003 to .125 thick),Stainless Steel (.012 to .062 thick ), Nickel(.002 to .004 thick) ,Brass (.020 to .062 thick )

Stamping,Die casting,Silk-screening, Anodizing, Laser craving,Engraving, Chemical Etching,Painting,Sandblasting,Brushing,CD craving and so on.

Mainly use water glue, hot melt adhesive, thermal tape, foam double-sided tape (PE foam double-sided tape, EVA foam double-sided tape, PU foam double-sided tape, acrylic foam double-sided tape, etc.) , Most customers will use hot melt adhesive and foam double-sided adhesive, both of which are environmentally friendly adhesives.

Matte, Semi-gloss, Gloss,Textured, Brushed

All custom nameplates available on any kind of shape with Holes, Slots, Round Corners, Die cuts, bends.

We will match any PMS or NCS color.

Do you need to order a custom nameplate in any shape? Please contact us as soon as possible, our goal is to always provide you with the highest quality nameplate.

Our high-power laser cutting machine can process any nameplate of standard shapes/materials for you.

People also ask

The main process shows as below

Step 1:St.St. plate

Step 2:Laser cut according to the engineering dwg

Step 3:Film or coating in the dust-free shop, light exposure imaging

Step 4:Etching, ie, remove material by way of chemical reaction or physical corrosion

Step 7:Industry oven, hi-temp, low-temp & constant temp.

Step 5:Get deepened by etching once, and texture finish by twice etching, like snow grain.

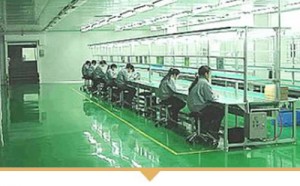

Step 8:Professional inspectors and packaging workers

Step 6:Done in the dust-free shop, by professional workers and advanced equipment

Step 9:Applied as precision etched parts for the electronic thin components for the aviation industry, machinery and chemical industry