Metal name tags,Grey anodized and diamond cutting nameplate | WEIHUA

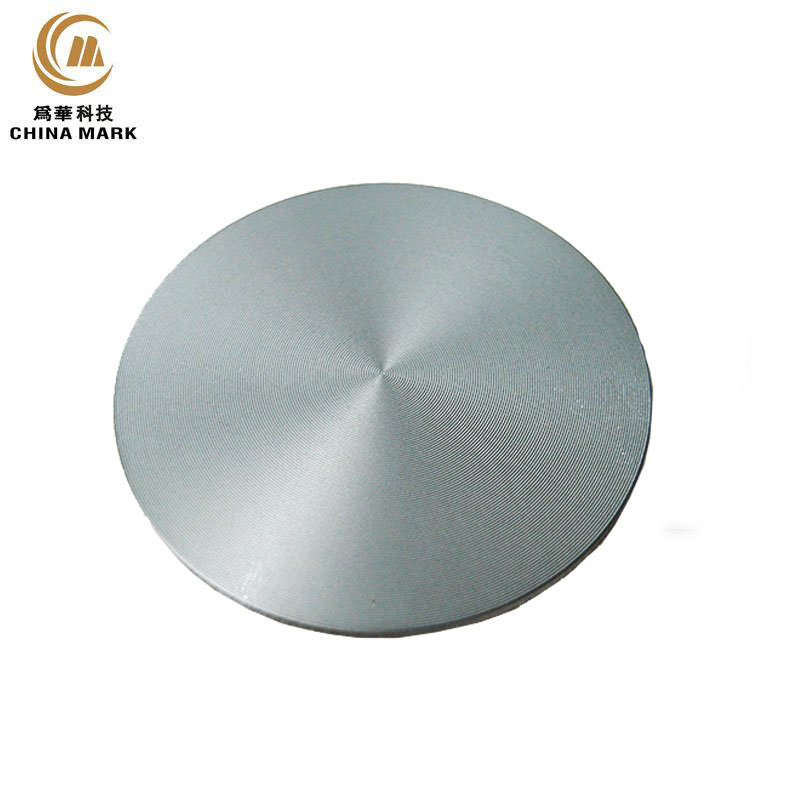

CD pattern signs mainly have the following characteristics:

(1) The main materials are aluminum, stainless steel and copper

(2) Printing form: CD pattern, chamfering, high gloss, oxidation, car pattern

(3) CD pattern: high-gloss CD pattern, chamfered CD pattern, oxidized CD pattern

(4) Specifications: It is possible to customize different product specifications according to customer requirements, and its grain spacing is determined according to the appearance and size of the product.

(5) Slope: generally 45°

(6) Application range: Mainly used in various hardware, small decorations, aluminum, copper, steel, mobile phone shells, MP3, MP4 and other shells, digital camera shells, key switches, audio decorations, earphone decorations, Kitchenware decorations, etc.

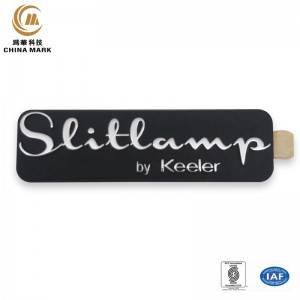

Personalized or company customized metal tags

Optional process: CD texture, anodizing, stamping, polishing, engraving, chemical etching, etc.

Available shapes: square, rectangle, irregular shape, round,oval

Uses: furniture signs, home appliances signs, audio headset signs, handicrafts, car decorations, luggage signs, etc.

Optional materials: aluminum, aluminum alloy, stainless steel, copper, iron, nickel and other materials

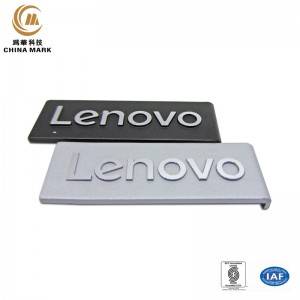

Optional processes: stamping, forging, electroforming, laser carving, oil injection, etching, etc.

Available shapes: square, rectangle, irregular shape, round,oval

Uses: furniture signs, home appliances signs, audio headset signs, handicrafts, car decorations, luggage signs, etc.

Optional materials: aluminum, aluminum alloy, stainless steel, copper, iron, nickel and other materials

Optional process: stamping, forging, laser carving, electroforming, etching, anodizing, silk screen, etc.

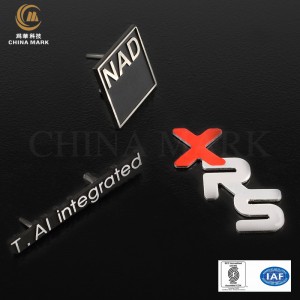

Available shapes: square, rectangle, irregular shape, round,oval

Uses: furniture signs, home appliances signs, audio headset signs, handicrafts, car decorations, luggage signs, etc.

Optional materials: aluminum, aluminum alloy, stainless steel, copper, nickel and other materials

Optional process: stamping, forging, electroforming, wire drawing, laser carving, etching, anodizing, silk screen, polishing, batch flower, CD texture, electroplating, etc.

Available shapes: square, rectangle, irregular shape, round,oval

Uses: furniture signs, home appliances signs, audio headset signs, handicrafts, car decorations, luggage signs, etc.

Optional materials: aluminum, aluminum alloy, stainless steel, copper, nickel and other materials.

Optional process: anodizing, spraying, stamping, forging, laser carving, etching, silk screen, wire drawing, polishing, engraving, electroplating, etc.

Available shapes: square, rectangle, irregular shape, round,oval

Uses: furniture signs, home appliances signs, audio headset signs, handicrafts, car decorations, luggage signs, etc.

Optional materials: aluminum, aluminum alloy, stainless steel, copper, nickel and other materials.

We mainly produce hardware signs covering different types of crafts. If you need custom metal label, you can tell the following details to us, and we will work out the most suitable signs according to your requirements.

Following details to us for custom metal label:

For example, is it used on audio equipment, mechanical equipment, or outdoors where long-term exposure is required? etc?

Such as mirror effect, matte effect, brushed effect, etc.

Please provide us with 2D/3D drawings

Please provide us with Pantone color number.

Such as stamping, forging, brushing, engraving, anodizing, CD pattern and so on. If you are not sure, we can also provide you with a suitable production process and production plan according to your sign purpose and the sign effect you want to achieve.

If you are not sure about your sign design, you can log on to our website (www.xy855.com) to browse, then select the sign you want, send email (wh@chinamark.com.cn) or call (0086+19926691505) for consultation from our business staff , then we can obtain the most suitable sign design for you. Our professional business and engineering staff will provide a sign design scheme suitable for you according to your requirements.

Learn more about WEIHUA products

The main process shows as below

Step 1:St.St. plate

Step 2:Laser cut according to the engineering dwg

Step 3:Film or coating in the dust-free shop, light exposure imaging

Step 4:Etching, ie, remove material by way of chemical reaction or physical corrosion

Step 7:Industry oven, hi-temp, low-temp & constant temp.

Step 5:Get deepened by etching once, and texture finish by twice etching, like snow grain.

Step 8:Professional inspectors and packaging workers

Step 6:Done in the dust-free shop, by professional workers and advanced equipment

Step 9:Applied as precision etched parts for the electronic thin components for the aviation industry, machinery and chemical industry