1. We will modulate the ink according to other color needs such as Pantone number or customer-provided color plates to adjust the appropriate ink and record the ink parameters

2. Send the color board sample to the customer, confirmation can be made goods

3.We will decide whether to use spray manual painting way or automatic spraying machine painting way according to the order qty and customer sign requirements.

If it is manual spraying, this is very suitable for customers with small order volume; and machine spraying, very suitable for customers with large order needs. and the product color consistency and uniformity will be good

4.After spraying, the aluminum nameplate need to go into the baking furnace for baking

5. After baking, according to the customer's test requirements to decide whether to do butanone, hundreds, friction resistance or the salt test.

Learn more about WEIHUA products

Read more news

The main process shows as below

Step 1:Alum plate

Step 2:Laser cut according to engineering dwg

Step 3:Air-driven punching machine

Step 4:Forging device

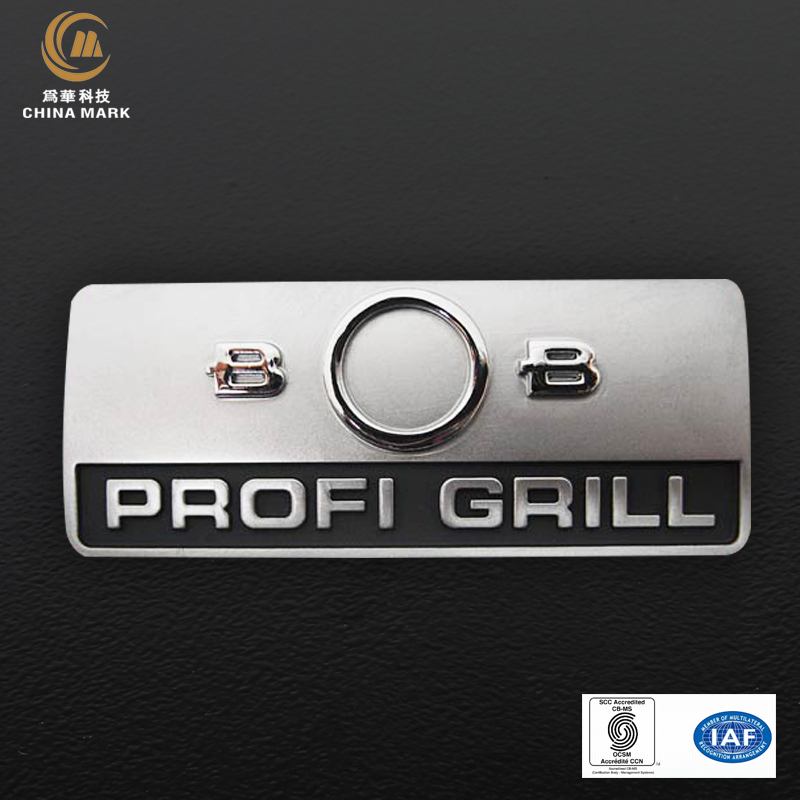

Step 7:Exquisite nameplate

Step 5:Auto line of anodic oxide processing

Step 8:Professional inspectors and packaging workers

Step 6:Auto oil-dripping machine

“Our 40,000 square meters facility has the capabilities to meet all your extrusion aluminum, logo plates,precision stamping needs coupled with multiple fabrication options to produce high-quality products solutions. ”

― WEIHUA

Post time: Nov-24-2021