Ts'ebetso ea t?epe ea extrusion ke eng?

Ho nt?oa ha t?epesebetsa ke mokhoa oa bohlokoa oa ho e lokisa khatello sebelisa molao-motheo oa t?epe polasetiki eaba ba etsa. Lisebelisoa tsa t?epe li sebetsoa ka methapo, melamu, lifaele tse bopehileng joaloka T, L le sebopeho se seng ka nako e le ngoe ka extrusion.

Metal extrusion o tobetsa ke thepa ea bohlokoa ka ho fetisisa ho hlokomela t?epe extrusion sebetsa Extrusion ke o mong oa mekhoa e ka sehloohong bakeng sa tlhahiso ea t?epe bao e seng ferrous le thepa celik le thehoa le ho e lokisa ea likarolo.

Hape ke mokhoa oa bohlokoa oa ho hlophisa le ho sebetsana le lisebelisoa tse tsoetseng pele joalo ka lisebelisoa tse fapaneng tsa likarolo le lisebelisoa tsa phofo.

Ho tsoa ho extrusion e chesang ea li-ingots tsa t?epe tse kholohali, extrusion e chesang ea lipompo tse kholo le lifaele tsa molamu ho extrusion e batang ea likarolo tse nyane tse nepahetseng, ho tiisa ka kotloloho le ho etsa thepa ea likarolo tse ngata ho tloha phofo le lipelete ho ea ho metsoako ea li-intermetallic, Bakeng sa ho thatafalloa lisebelisuoa tsa ts'ebetso tse kang thepa ea supondonding, theknoloji ea sejoale-joale ea extrusion e sebelisoa haholo.

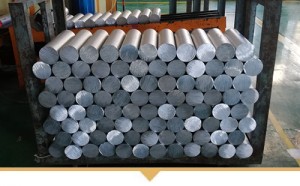

Kemiso ea aluminium e nt?itsoeng ka ntle

Ho latela tataiso ea phallo ea polasetiki ea t?epe, extrusion e ka aroloa ka mekhahlelo e latelang:

Extrusion e ntle:

Nakong ea tlhahiso, tataiso ea phallo ea t?epe e ts'oana le ea litebele

Extrusion ea morao:

Nakong ea tlhahiso, tataiso ea phallo ea t?epe e fapana le ea litebele

Extrusion ea motsoako:

Nakong ea tlhahiso, phallo ea karolo ea sekheo e ts'oana le ea litebele, 'me karolo e' ngoe ea t?epe e phalla ka lehlakoreng le leng la kotlo.

Radial extrusion:

Nakong ea tlhahiso, tataiso ea phallo ea t?epe e likhato tse 90 ho ea ho motsamao oa litebele.