Theknoloji ea Weihua - Khampani ea machining ea China e nepahetseng; Re fana ka lits'ebeletso tsa machining tsa CNC, ho betla ka nepo, ho sebetsana ka nepo le mefuta e fapaneng ea likarolo tsa likarolo, ts'ebeliso ea sistimi ea ERP ho kenya t?ebetsong tlhahiso ea bongata le tsamaiso, phetiso e khuts'oane, boleng bo holimo, ka tieo labalabela ho sebelisana le uena!

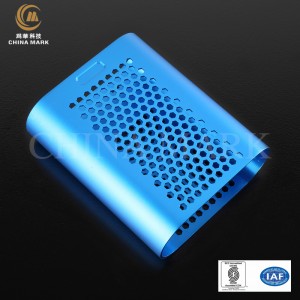

Lintlha tsa likarolo tse nepahetseng tsa t?epe le likarolo tsa ho taka li sebetsoa ka botebo

Likarolo tsa stamping tsa t?epe, likarolo tse otlolohileng li sebelisoa haholo bophelong, empa ts'ebetso ea ts'ebetso e batla e le mpe, bokaholimo ba mosebetsi bo bonolo ho ngoapa. Hlobo e bonolo ho hlaha hlama e khomarelang, e baka boleng ba t?ebetso le ts'ebetso ea ts'ebetso li amehe Ho ntlafatsa boleng ba t?ebetso le ho shoa, sebopeho se shoang, lisebelisoa tse shoang, kalafo ea mocheso le setlolo se lokela ho ntlafatsoa.

Mathata a hlokang ho tsotelloa ha ho sebetsoa ka botebo ba likarolo tsa t?epe tse nepahetseng le likarolo tsa ho taka:

Morero oa thepa e sa tsoakoang ea t?epe e sa hloekang ho fihlela thepa e sa sebelisoang e tloaelehileng ea machabeng, ho hatakela ho sebetsa ho tlameha ho ba bonolo.

Shoa sebopeho le tapa lebelo ke ho ntlafatsa le bothata ba ho kotokaka, kahoo ho molemo ho etsa holim blanking tsa lesale blanking oblique, kotokaka letho tlas'a bohato ba lesale blanking le holim blanking tsa concave shoa ka ho ikopanya le feletseng, ka etsa hore thepa ea sekhutlo e shoeleng ea concave e be le matla a batlang a le maholo haholo.

Ts'ebetsong ea ho tapa le ho taka ka nepo ea t?epe, hlobo e khomarelang e tebile, e lebisang ho tahlehelo e tebileng ea hlobo ebe e etsa hore likarolo tse tapa li be mpe. Anti - Lisebelisoa tsa viscosity: sehlopha sa alloy sa koporo, 3054 alloy t?epe ea t?epe le lisebelisoa tse ling.

Ha u hatakela karolo ea ho taka e lokela ho ba e loketseng ho sebelisa oli e tlotsang, e ka fokotsa sekhahla sa khohlano lipakeng tsa thepa le hlobo, e le ho fokotsa matla a ho taka; Ka kakaretso thepa e koahetsoe ka oli, ebe e kenella set?oant?ong se shoang. Haeba litlhokahalo tsa boleng ba bokaholimo e se likarolo tse phahameng tsa sekontiri se tebileng, ho sebetsana le litebele ho ke ke ha sebelisa oli e tlotsang; Ho molemo ho fokotsa sekhahla sa ho taka.

Ts'ebetsong ea ho taka, ho thibela ho petsoha le ho phatloha ha likarolo tse betliloeng tsa t?epe ka nepo, re tlameha ho hlophisa ts'ebetso ea mahlale, re khethe coefficient e nepahetseng ea ho taka, 'me re tsamaise annealing e loketseng ea mantlha Ka kakaretso, coefficient ea pele ea ho taka ea likarolo tse nepahetseng tsa ho tapa e ka khethoa hore e be haufi le moeli o tlase.

?